Centexbel-VKC’s pilot extrusion lines offer the industry a useful, cost and time efficient platform to:

- evaluate the spinnability of new polymer grades and recyclates

- evaluate the processability and properties of new masterbatches

- produce prototype yarns in view of further testing

- optimise the extrusion process

The extrusion lines rapidly produce samples with few materials for prototyping and testing!

Because the extrusion platform is fully integrated in Centexbel-VKC’s organisation, all material samples and prototypes can be submitted to relevant testing during each processing step. The results are then discussed with the Centexbel-VKC researchers and technological experts for subsequent improvement, valorisation and industrial upgrading.

Monofilament extrusion line with unique features for R&D and Prototyping

The 18 meter long extrusion line includes several options to produce innovating textiles and is equipped with unique features that are seldom seen in industrial lines!

Extrusion line for the production of monofilaments, bicomponent yarns and tapes

The extrusion line was purchased in the frame of the Interreg project Accelerate³ to develop innovating functionalized filaments mainly from biopolymers for 3D printing with varying degrees of softness and flexibility.

The 18 meter long extrusion line includes several options to produce innovating textiles, including mono- and bi-component fibres, monofilaments, tapes, multifilament bundles and is equipped with really unique features that are rarely present on industrial lines:

- Two extruders allow a large variety of polymer flow rates for pilot scale productions from 0.250 to ± 5 kg / hour. The low flow rates are especially important to process experimental products, that are only available in very limited quantities. It also includes the possibility to extrude both thick (several mm) and thin (< 40 µm) filaments. In addition to filaments, the extruder is suited to produce filament bundles, films and cut tapes.

- The extrudate can be cooled in several ways:

- a standard cooling water bath with temperature range from 15 to 70°C

- possibility to switch to a cooling drum with the same temperature range or air cooling or a combination of both methods

- The filaments are drawn by means of four roller sets, each with an adjustable temperature and intermediate ovens allowing the process to take place in several steps to optimize both strength and stability.

- The thermal treatment takes place in hot-air or steam ovens, allowing to proceed to a 3-step drawing to maximize the mechanical properties and thermal stability of the yarns.

- The filaments are then guided to a winding station with 4 positions for monofilament (bundles) or to a winding device for films.

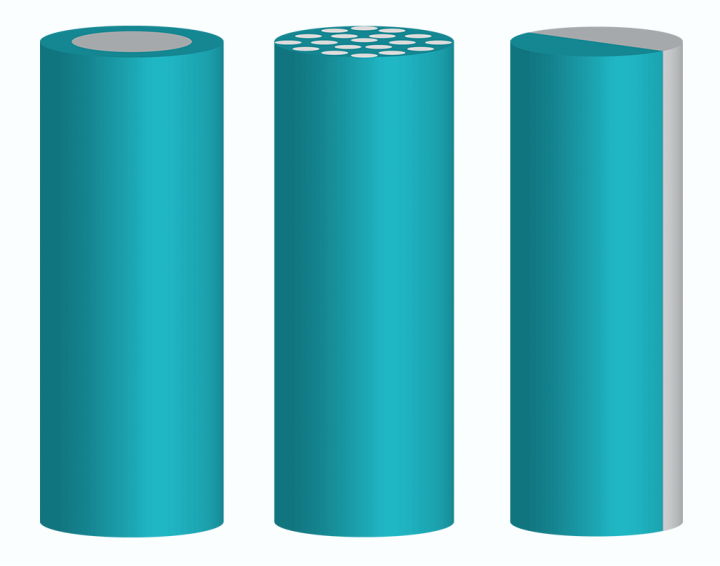

The extrusion line is also suited to produce bicomponent fibres, made from two different polymer grades that are present over the entire length of the filament according to a determined pattern. By extruding both polymers to form one single filament, their different properties will be combined. The final properties and applications depend on the properties of the different polymer grades and on the shape of the cross-section (see image).

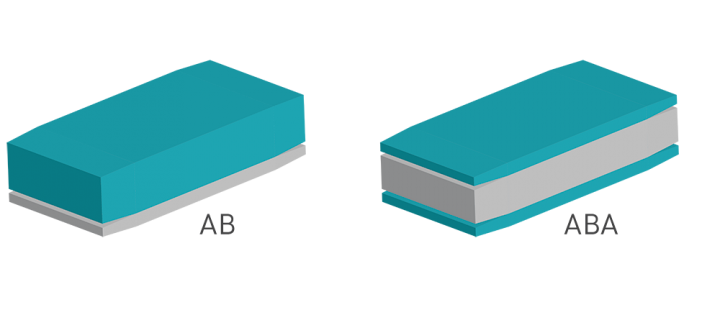

The line is equiped with spinnerets to co-extrude films with an A, A-B and A-B-A-structure upto 50 mm.

Flexible twin screw compounder

Closely intermeshing, co-rotating twin screw extruder with multiple design possibilities

Technical specifications:

- L = 40 mm / D = 18mm

- Side extruder

- 3 feeders for powder/pellets

- Degassing: Vacuum or Atmospheric

- Waterbath + pelletizer

- Throughput: 2 to 10 kg/h

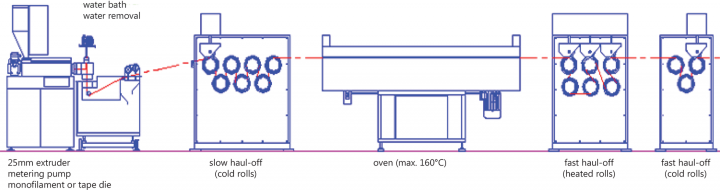

Tape & monofilament line

The semi-industrial tape and monofilament line is used to produce prototypes with low amounts of material (0.6 to 5 kg/h) and can be equiped with different types of spinheads (from 1 (round/tape) to 300 spinholes. The height of the water bath can be adjusted).

Extrusion and drawing conditions:

- slow haul-off (1 to 75m/min); 7 cold rolls

- heated oven (max. 200°C)

- flexible fast haul-off (10 to 200m/min) - nip roll per pair of rolls

- individually heated rolls (allows annealing)

- speed setting per roll pair (allows stretching/relaxation)

- extra fast haul-off (3 cold rolls): stabilisation/relaxation before winding

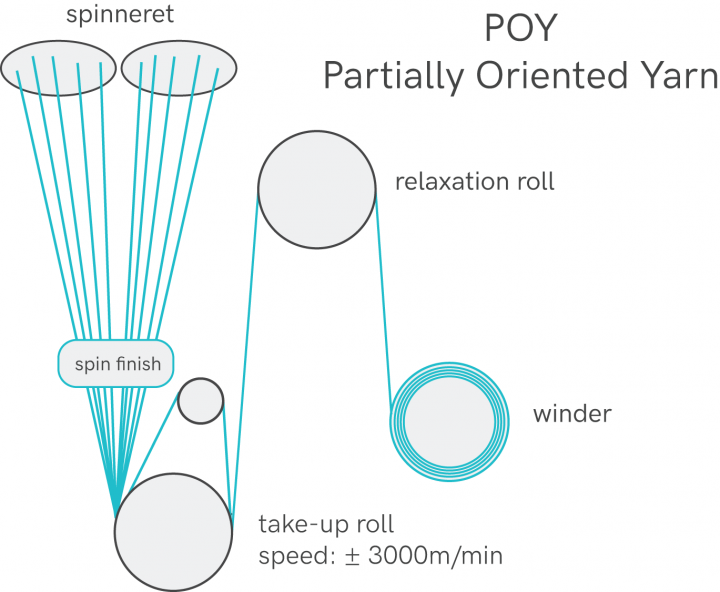

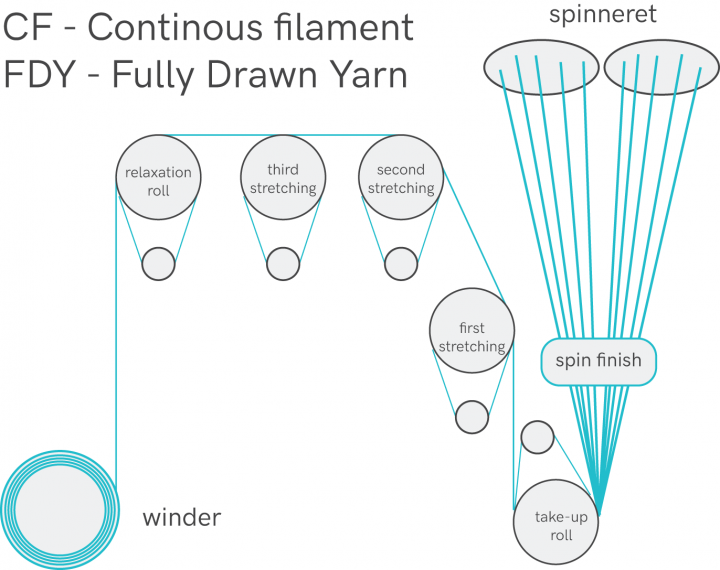

Multifilament line : SPINMASTER

The Spinmaster is a uniquely configurated multifilament pilot line designed to extrude BCF carpet yarns as well as flat CF and POY yarns.

Technical specifications:

- High temperature processing: up to 400 °C

- Speed: up to 3500 m/min

- 3-step yarn drawing

- Production output: 1 – 20 kg/h

Composite press

The Centexbel-VKC composite press is perfectly suited to treat both woven and non-woven fabrics as well as unidirectional textiles. Furthermore, the polymer plates can be pressed in view of rotational rheology.

One-directional composites are generally best suited for research. The mechanical properties of these composites can be readily interpreted and it is also possible to work directly on yarn level, without having to produce a fabric first. Centexbel-VKC is able to process the polymer in both fibre as film form.

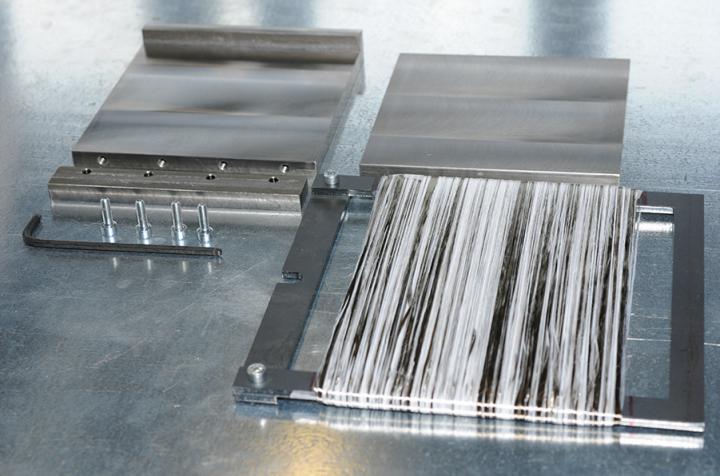

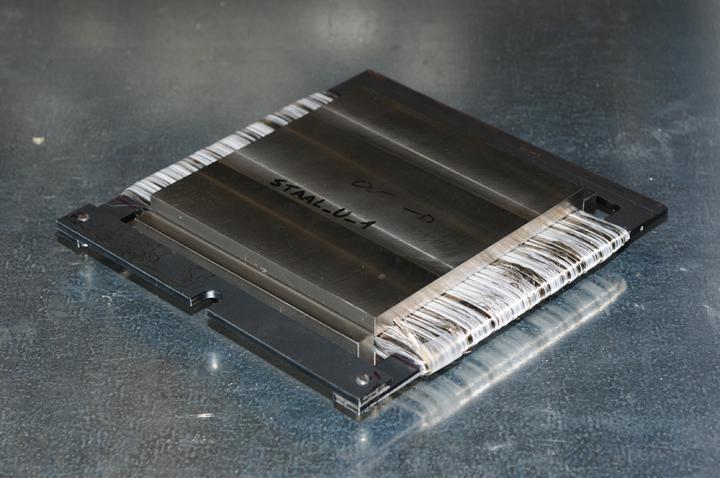

Unidirectional composites

The operation procedure to produce a UD-plate (or unidirectional composite plate) includes the following steps:

- a number of layers consisting of reinforcing and matrix yarns are winded around a frame. The number of layers needed to obtain a certain thickness can be easily computed.

- the pre-form is then placed in a specially developed mould that can be opened for easy demoulding

- the fibres are cut loose from the frame. This needs to be executed very carefully to prevent fibre disorientation

- the mould is placed into the press where it is submitted to a preset press cycle. The press cycle is characterised by a set pressing pressure, temperature and duration.

Characteristics of the Centexbel-VKC LabPress:

- Max temperature: 300°C

- ΔT/Δt = max 10°C/min

- pressure: 30-600 kN (2 – 300 bar)