Fibre reinforced thermoset composites (FRTCs) are attractive materials for high demanding sectors, such as automotive or construction, because of their lightweight and excellent mechanical properties. However, the lack of reprocessability and difficulty for repairing and recycling significantly increases the overall material cost and causes grave environmental concerns. Additionally, the vast majority of polymer matrices and fibres used in their manufacturing are non-renewable fossil-derived materials or require high amounts of energy for their production.

By involving the European bio-based industry, ECOXY will develop innovative bio-based epoxy resins and fibre reinforcements to produce new sustainable and techno-economically competitive FRTCs by targeting advanced functionalities: reparability, reprocessability and recyclability (3R).

The 3R functionalities will be achieved by using new resin formulations replacing commonly used curing agents by dynamic hardeners, which under certain operational makes possible to:

- repair fibre/matrix delamination and matrix micro-cracks

- reprocess cured laminates to create new 3D parts (impossible with traditional FRTCs)

- mechanical and chemical recycling

Thus, ECOXY will develop

- tailor-made bio-based epoxy monomers (including biorefinery products)

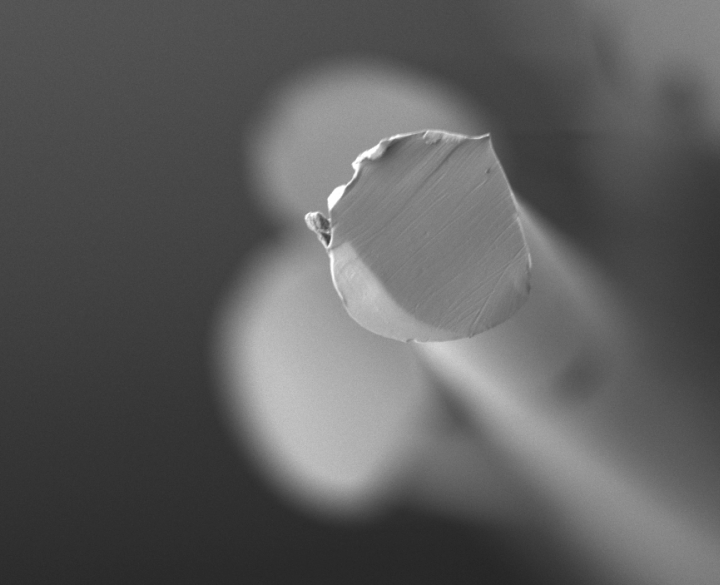

- upgraded and functional bio-based fibres (natural and PLA)

- specific formulations for FRTCs manufacturing processes (RTM, wet compression moulding and pultrusion)

- additional functionalities such as flame-retardancy for 3R resin and self healing for fibres

The selected prototypes will be validated for automotive and construction sectors using relevant standards and applicable certifications. Besides, an environmental (LCA) and socio-economic assessment of the results will be carried out.

The project is funded by H2020-BBI-JTI-2016 / BBI-RIA - Bio-based Industries Research and Innovation action

The Belgian industrial participant is WEVERIJ FLIPTS EN DOBBELS