Applicant: Soudal NV

Inventor(s): Yves De Smet; Luc Thys; Peter Maria Ivan Brughmans; Rob Labots

Patent application number: BE1030436

Publication date: 2023-11-06

The problem

Cartridges made of high-density polyethylene (HDPE) are currently used for dosing adhesives and sealants. HDPE can be recycled, but this depends on a few key criteria. The first and most important condition is that the waste must be disposed of properly. Unfortunately, most users do not meet this requirement because HDPE waste is often contaminated with other types of waste. Even when the discarded HDPE cartridges are collected via the appropriate waste channels, there remain challenges mainly because these cartridges must be completely emptied before the start of the recycling process. Most plastic cleaning processes are based on the float-sink tank systems where impurities can usually be removed by letting HDPE float in water. However, HDPE cartridges are often too contaminated by the adhesives and sealant they contain. Persistent residual products mostly fully dried out and/or hardened cannot be separated from the plastic. Consequently, most of this plastic waste cannot be recycled. Hence there is a need for a reliable recycling process for this type of plastic waste.

There is an increasing demand for recycled plastics, such as polyethylene (PE) and polypropylene (PP) for use in caulking cartridges to reduce the use of new plastics as well as the carbon footprint of packaging.

The solution

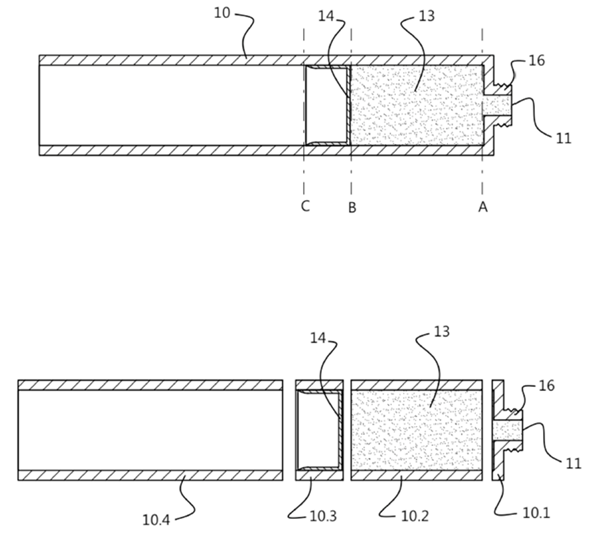

The invention relates to a method of recycling a cartridge for use in a cartridge gun, wherein the cartridge is composed of a plastic material, and comprises a housing (10) having a front (16) with an outlet (11), and a rear in the form of a plunger (14), the cartridge containing residual material (13), the method comprising:

- cutting the housing (10) transversely to the longitudinal axis of the housing into 4 parts (10.1), ( 10.2), (10.3) and (10.4), where part (10.1) includes front (16) with exhaust (11); wherein part (10.2) comprises the part of the housing that contains residual material (13); wherein part (10.3) includes the part of the housing containing plunger (14), and part (10.4) includes the remainder of the housing;

- collecting at least one of the parts (10.1), (10.2), (10.3) or (10.4),

- removing the residual material (13) of the collected part or parts, and

- reusing the plastic from the collected part or parts from which the residual material (13) has been removed.

The invention also relates to cartridges made from material comprising plastic material recycled from parts (10.1), (10.2), (10.3) and/or (10.4) collected by the method of the present invention. Furthermore, the invention relates to sealants or adhesives comprising residual material (13) collected and recycled using the method of the present invention. Such products can be used in a new cartridge, preferably one whose housing consists of recycled materials.

The present invention can also be implemented for cartridges containing other liquid substances such as paints and decorative materials and the like. In particular, the invention relates to cartridges containing difficult to remove materials such as sealants and glues. The current procedure is preferably implemented via a continuous or semi-continuous process. The process is preferably automated with identical cartridges positioned onto a conveyor belt so that the front sides of the cartridges are in the same direction.