Applicant: PICANOL

Inventor(s): DEMEERSSEMAN PAVEL; DEGRAEVE BRAM; BROUCKAERT ROBBE

Patent number: EP4310233

Publication date: 2024-01-24

The invention relates to a weaving machine that includes an insertion element, such as a gripper, and a device for selecting and presenting weft threads to the insertion element.

The problem

US5400834 patent describes a device used in weaving machines to select and present weft threads to an insertion element. The device consists of multiple weft feeder modules, each containing a weft feeder element with a weft thread guide at its distal end, an eccentric drive mechanism, a drive motor, and a guide structure for the weft feeder element. Each weft feeder module includes a support plate. The drive motor is attached to one side of the support plate, while the weft feeder element and guide structure are located on the opposite side. The support plates of all weft feeder modules are mounted between two holding plates, which are also secured by screws. The holding plates are connected to each other by crossbars. The holding plate is attached to a machine frame using screws.

EP2893067 B1 presents an alternative method for selecting and presenting weft threads to an insertion element in a weaving machine.

EP0896075 A2 describes a device used to select and present weft threads to an insertion element of a weaving machine. The device includes a holding plate and multiple weft feeder modules, each with a drive motor. All drive motors are mounted to the common holding plate.

The invention aims to provide a compact and user-friendly device for selecting and presenting weft threads. Additionally, the invention aims to provide a weaving machine equipped with this device.

The solution

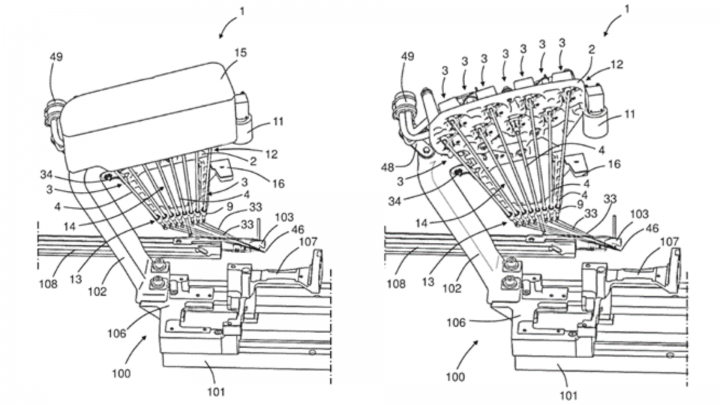

The invention relates to a device (1) for selecting and presenting weft threads to an insertion element (103) of a weaving machine comprising a holding plate (2) and a number of weft feeder modules (3), each weft feeder module (3) comprising a weft feeder element (4) with a weft thread guide (5) at its distal end, a drive mechanism (6), a drive motor (8), which drive motor (8) is mounted to the holding plate (2) in a motor mounting region (12), and a guide structure (9) mounted to the holding plate (2) in a guide structure mounting region (13), wherein the weft feeder element (4) is connected via the drive mechanism (6) to the drive motor (8) for a movement of the weft feeder element (4) between a rest position and a presenting position, and wherein the weft feeder element (4) is guided by the guide structure (9), wherein an opening (14) is provided in the holding plate (2) between the motor mounting region (12) and the guide structure mounting region (13) allowing incidence of light to improve a visibility in a thread feeding zone.

The invention further relates to a weaving machine comprising an insertion element (103), in particular a gripper, and a device (1) for selecting and presenting weft threads to the insertion element (103). The invention relates to a device for selecting and presenting weft threads to an insertion element of a weaving machine. The invention further relates to a weaving machine comprising an insertion element, in particular a gripper, and a device for selecting and presenting weft threads to the insertion element.

In this device embodiment, the weft feeder modules can be easily attached or detached as a whole from the holding plate via the drive motor and guide structure. This means that the weft feeder module can be assembled separately from the weaving machine and then mounted onto the holding plate, which is in turn attached to the weaving machine frame. In case of wear and tear, the weft feeder module can be detached from the holding plate and replaced.

The guide structure includes a bearing bush that slides to receive the weft feeder element. The bearing bush is mounted rotatably to the fixation element using a pin that has an axis parallel to the motor axis of the drive motor. The pin can be mounted in the fixation element with high precision. The fixation element has a pin opening to receive the pin. The gap covered by the fixation element has a larger diameter than the pin opening. The gap enables detachment of the guide structure from the holding plate without the need to move the pin solely in a direction perpendicular to the holding plate. The fixation element, to which the pin is rotatably mounted, ensures precise support of the pin.

A weaving machine is provided with an insertion element, such as a gripper, and a device for selecting and presenting weft threads to the insertion element. The device is detachably mounted to a cross beam of the weaving machine via a support arm. The support arm has a first section extending upwards from the cross beam and a second section extending transverse to the first section.

Advantages

- In this embodiment, a light source is attached to the holding plate to illuminate the thread feeding zone, improving visibility.

- Additionally, a camera is attached to the holding plate to take advantage of the improved visibility and capture images of the thread feeding zone. The camera's pictures can be viewed on the weaving machine's display or a peripheral device. Slow motion viewing is also available, allowing for detailed analysis of the thread feeding processes, especially in the threading and presenting zones.

- The device includes multiple weft feeder modules attached in a staggered arrangement to the holding plate, resulting in a compact design.