The transition to a more sustainable and circular economy is taking place in all sectors through innovations that have a positive impact on both businesses and the planet. For textiles and plastics, a quick search of patent trends in 20231 showed that the majority of cooperative patent classifications (CPC) classes were in class Y02, which is for technologies or applications for mitigation or adaptation against climate change.

This clearly shows that most of the patented innovations in textiles and plastics were aimed at making these industries more sustainable.

More specifically, the top five CPC classes for both textiles and plastics patents were as follows:

- Y02W30/66: Disintegrating fiber-containing textile articles to obtain fibers for re-use

- Y02W30/62: Technologies for solid waste management – plastics recycling, rubber recycling

- Y02P70/62: Climate change mitigation technologies in the production process for final industrial or consumer products – related technologies for production or treatment of textile or flexible materials or products thereof, including footwear

- Y02P70/10: Greenhouse gas capture, material saving, heat recovery or other energy efficient measures

- Y02E60/10: Enabling technologies; Technologies with a potential or indirect contribution to greenhouse gas emissions mitigation – energy storage using batteries

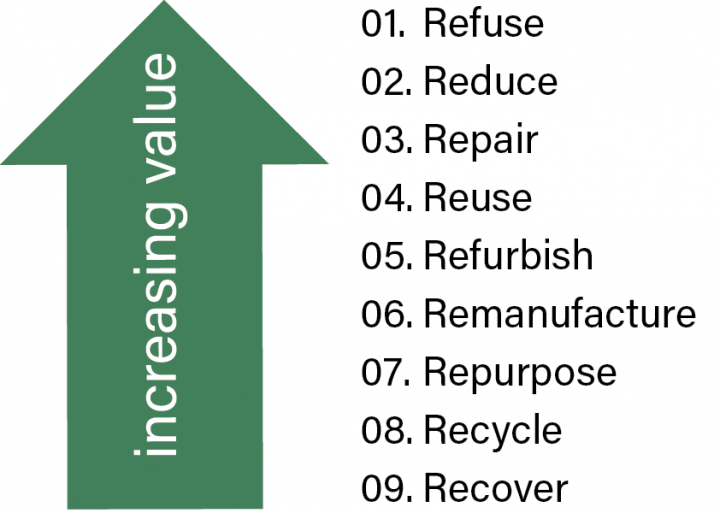

Based on these five most frequent classes, an advanced search2 was performed to get a more detailed trend on technologies related to both textiles and plastics. Most of the innovations were related to recycling. However, in the hierarchy of so-called R-strategies (Figure 1) for the circular economy, recycling is the next but last strategy before energy recovery through incineration. These strategies guide decision-making on circular business models3 with the aim of keeping a product at its highest value for as long as possible, i.e. extending the period during which a product performs the function for which it was manufactured in the first place.

Figure 1: R-strategies hierarchy with the goal of keeping the product at its highest value as long as possible

Therefore, other strategies such as reuse or refurbishment to reduce waste must be considered before recycling. Before the recycling process can start, several steps are essential to ensure that high quality waste is obtained. These steps include (i) collecting the waste, (ii) sorting the (mixed) waste (e.g. by composition, colour, dimensions), (iii) cleaning or dismantling the waste to remove unwanted parts such as buttons and zips for textiles, residual liquids in plastic containers. A selection of inventions relating to these important pre-recycling steps are described below.

- Two separate quick searches for patent trends for textiles and plastics was performed using Google lens for the period 2022-12-01 to 2023-12-11 with “textile” and “plastic” for each of the searches. The three most preponderant CPC classes were identified for each search. It turned out that one of the top three classes was common for both “textile” and “plastic” searches, namely Y02P70/10.

- The advanced search was performed using Orbit Intelligence version 1.9.8. combining classes, key words, data filtering and analysis to identify the most relevant patents published between 2022-12-01 and 2023-12-11 related to textiles and plastics.

- These R-strategies in relation with circular economy business models were published by Circle Economy Foundation in 2026. Read full report

Arrangement and method for collecting and crushing waste material

Patent Number: EP4215458

Publication date: 2023-07-26

Applicant(s): FF FUTURE OY

Inventor(s): NIEMINEN HENRI

Abstract

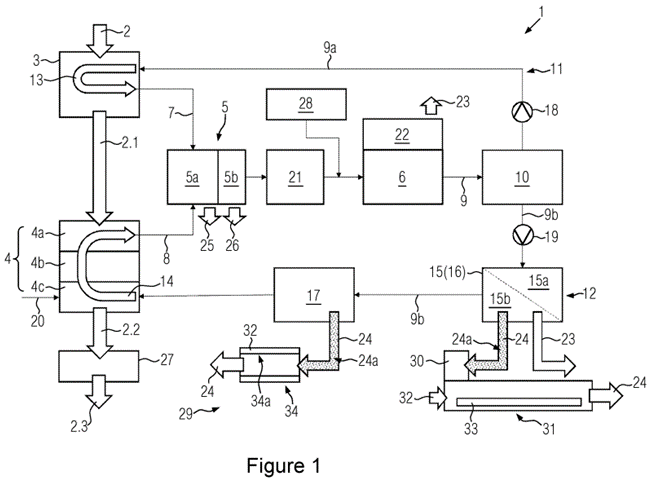

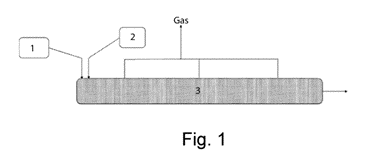

Arrangement and method for collecting and crushing waste material comprising foam plastic and/or foam insulation. The arrangement comprises a shipping container (1), a first apparatus (2) arranged into the shipping container for crushing waste material into smaller pieces, and a second apparatus (3) arranged into the shipping container for compressing crushed waste material. In the arrangement, the first apparatus (2) and the second apparatus (3) are arranged to move in the longitudinal direction of the shipping container (1), whereby the shipping container (1) is divided into three separate spaces (A, B, C) divided by the apparatuses, the volume of which spaces changes when the first apparatus (2) and/or the second apparatus (3) moves in the longitudinal direction of the shipping container.

Method and device for sorting mixed plastic packaging waste including foils

Patent Number: EP4129605

Publication date: 2023-02-08

Applicant(s): INDAVER PLASTICS RECYCLING NV

Inventor(s): GODDAERT ERIC; MEYVIS ELINE

Abstract

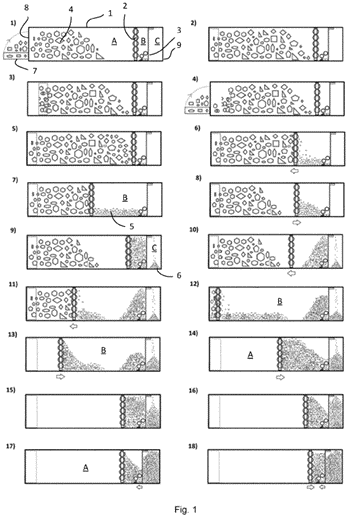

Method for sorting mixed plastic packaging waste comprising foils, wherein the mixed plastic packaging waste is first sorted by size into a number of size fractions and then by density into a number of density fractions, wherein sorting by size is carried out into five size fractions that differ from each other in size, wherein the four largest size fractions are further sorted by density, wherein a lower-density fraction and a higher-density fraction are obtained for each size fraction, wherein each lower-density fraction comprises at least 70 percent by weight foils, wherein the foils comprise PE foils and other foils.

Process and apparatus for crushing and cleaning waste plastic

Patent Number: EP4230374

Publication date: 2023-08-23

Applicant(s): KRONES AG

Inventor(s): FORSTHOEVEL JOCHEN; AUBURGER MICHAEL; FISCHER SIMON; RUSS MICHAEL; BAUR FRANZ

Abstract

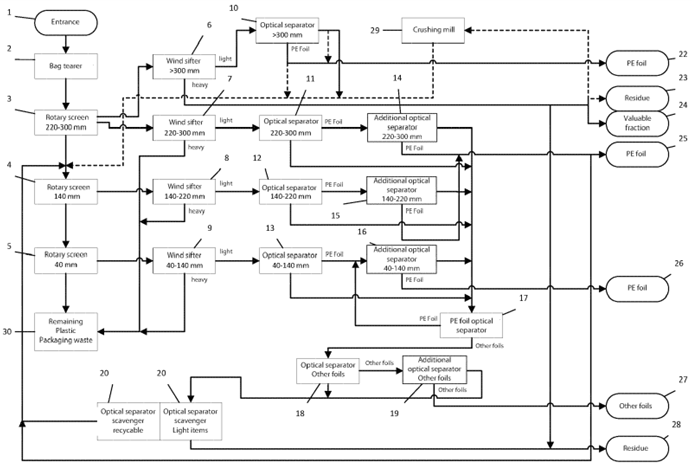

The invention relates to a method and a system for comminuting and cleaning waste plastic. For this purpose, used plastic is comminuted and prewashed in a wet mill and subsequently purified in a washing plant, in particular in a multi-stage manner, to obtain useful material. The resulting waste water is subjected to mechanical Filtration and Flotation and is then intermediately stored as circulating water. Based on this, a first portion of the circulating water is fed back to the wet mill as first process water and a second portion of the circulating water is fed back to the washing plant as second process water. As a result, the first and second portions of the reverse water can be adapted in a targeted manner to the respective water requirement of the wet mill and of the washing installation and to the required water qualities, if appropriate with selective post-purification of the second portion of the circulating water. As a result, the fresh water requirement for the method described can be minimized.

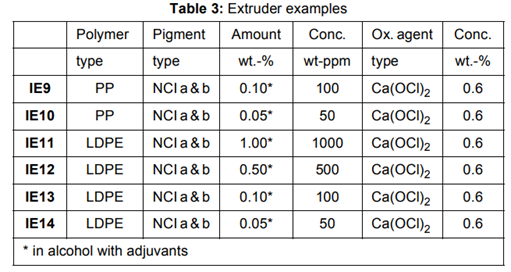

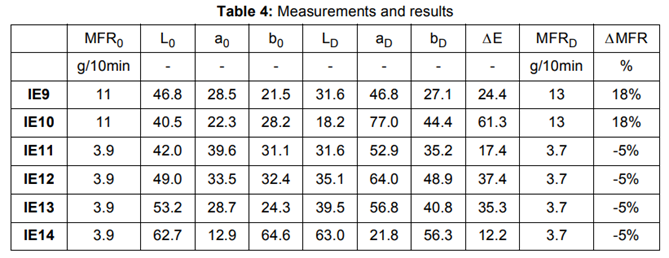

Decoloration of polyolefins in the melt state

Patent Number: EP4155340

Publication date: 2023-03-29

Applicant(s): BOREALIS AG

Inventor(s): KOLLER KERSTIN; BURGSTALLER CHRISTOPH; BRAUN HERMANN; DENIFL PETER; GAHLEITNER MARKUS

Abstract

The present invention concerns a process for decolorizing a polyolefin composition, the process comprising the steps of a) providing a polyolefin composition comprising at least one polyolefin and at least one organic chromophore, b) mixing the polyolefin composition in a melt state at a temperature of 170 to 290 °C with an inorganic oxidizing agent, wherein the inorganic oxidizing agent is selected from the group of inorganic peroxides and hypochlorites, and c) obtaining a decolorized polyolefin composition.

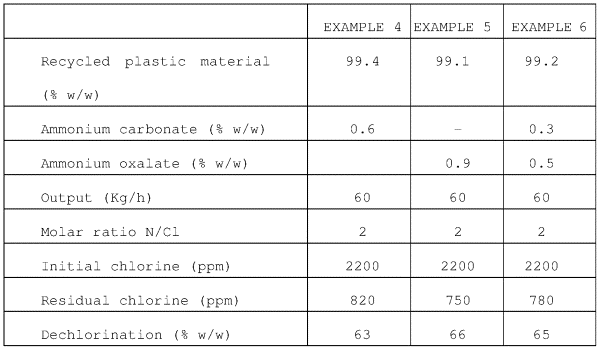

Process of dehalogenation of plastic materials including recycled ones, and use of one or more chemical compounds containing nitrogen as a dehalogenating agent of plastic materials including recycled ones

Patent Number: WO2023119123

Publication date: 2023-06-29

Applicant(s): ENI S.P.A.; VERSALIS S.P.A.

Inventor(s): SCAVELLO FRANCESCO; BALDUCCI DANIELE; MONTANARI ERICA

Abstract

A process involving the dehalogenation of plastic materials, or mixtures of plastic materials, including recycled ones, containing halogenated components is described, wherein during the heating to 150°C-450°C of the material to be treated, a dehalogenating agent containing nitrogen is added in such a quantity that the ratio between the moles of nitrogen of the dehalogenating agent and the sum of the moles of halogen contained in the plastic material is at least 1:1.

Coating film peeling method and coating film peeling device

Patent Number: WO2023218811

Publication date: 2023-11-16

Applicant(s): TORAY INDUSTRIES, INC.

Inventor(s): TANINO KIYOSHI; SUZUKI TADAMASA; HIGASHIDA YOSHIHISA; WATANABE KAZUTAKA

Abstract

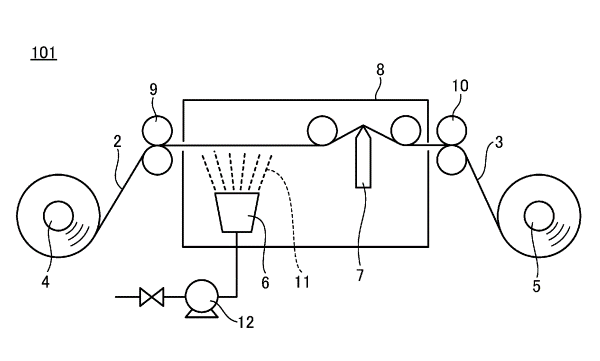

The present invention provides a coating film peeling method and a coating film peeling device with which it is possible to efficiently and reliably peel a coating film from a base film having a coating film, using a washing solution. A method for peeling a coating film from a base film having a coating film according to the present invention is for peeling a coating film from a base film having a coating film which has a coating film containing a water-soluble resin, and is characterized in that a washing solution is applied in a range of 3-650 mL/m2 to the surface of the coating film, then, while bringing a peeling member into direct contact with the coating film surface of the base film having a coating film and while making the angle formed by the base film via the peeling member be in the range of 20-150° and applying tension in the range of 10-1000 N/m in at least one longitudinal direction of the base film, moving the base film in the longitudinal direction of the base film relative to the peeling member to peel away the coating layer containing the washing solution.

Energy-efficient separation of polyolefins

Patent Number: EP4098689

Publication date: 2022-12-07

Applicant(s): Nederlandse Organisatie voor toegepast- natuurwetenschappelijk onderzoek TNO

Inventor(s): VAN DER MEER JOHANNES; KWAKERNAAT LAURAN; PRINS LUCIE; GEERS LEONARD FERDINAND GERARD; VAN DE RUNSTRAAT ANNEMIEKE; ROELANDS CORNELIS PETRUS MARCUS

Abstract

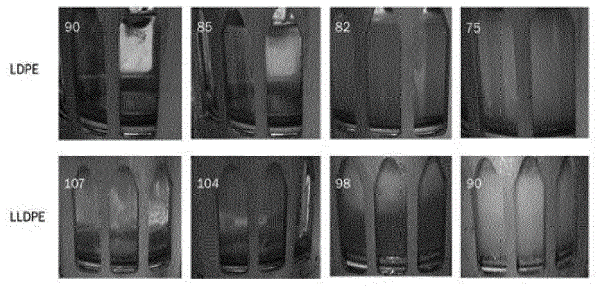

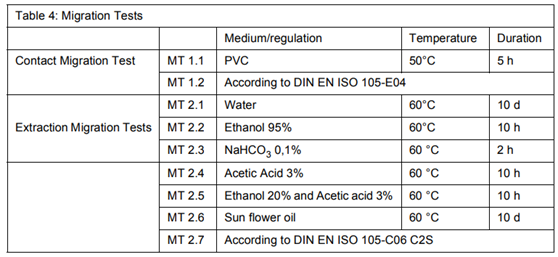

The invention is in the field of recycling plastic waste. In particular, the invention is directed to a method to separate polyolefins from plastic waste based on a dissolution/precipitation approach. The method according to the present invention may be used to separate polyolefins with a high selectivity by using at least a first and a second cooling surface. The invention is particularly suitable to at least partially separate LLDPE and LDPE or polypropylene and polyethylene from plastic waste.

Method for decoloring a colored plastic article having an outermost layer

Patent Number: EP4163325

Publication date: 2023-04-12

Applicant(s): SMART COLORING GMBH

Inventor(s): ROBERTZ BERND

Abstract

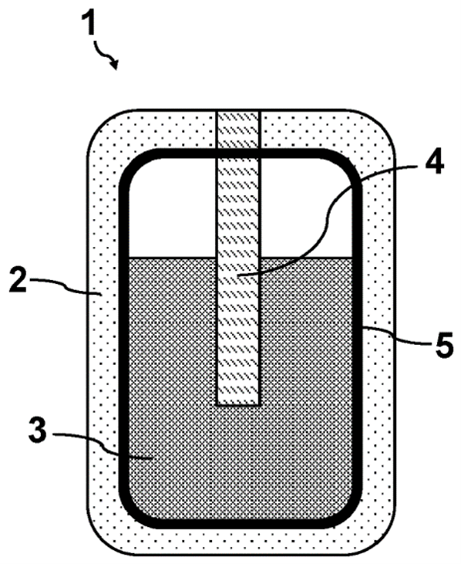

It is an object of the invention to provide a method for decoloring a colored plastic article, wherein the plastic article comprises at least two layers, wherein a first layer of the at least two layers is an outermost layer and forms a surface of the plastic article; wherein a second layer of the at least two layers is a color layer and comprises a plastic material and a coloring agent; wherein the plastic material comprises at least 0,1 wt.-% of a polar component, based on the weight of the plastic material, wherein the polar component is a polar polymer, a polar compound and/or a blend of polar polymers and/or polar compounds, wherein the polar polymer has a molecular weight Mw ≥ 1000 g/mol and has at least 5 wt.-% of heteroatoms based on the molecular weight of the polar polymer, wherein the polar compound has a molecular weight Mw < 1000 g/mol and has at least 5 wt.-% of heteroatoms based on the molecular weight of the polar compound, and wherein heteroatoms are any atoms except C and H atoms; wherein the coloring agent comprises an organic molecule with a molecular weight Mw ≤ 800 g/mol; wherein the outermost layer comprises a crosslinked silicon compound, wherein the crosslinked silicon compound comprises at least two silicon atoms bridged by an oxygen atom; the method comprising the steps ofa) shredding the colored plastic article to a granulate and/or a powder, b) exposing the granulate and/or powder to a decoloring bath for about ≥ 1 minute to about ≤ 240 minutes, wherein the decoloring bath has a temperature above a glass transition temperature Tg of the colored plastic article and below a melting temperature Tm and/or decomposition temperature of the colored plastic article and/or has a temperature ≥ 60 °C to ≤ 130°C,wherein the decoloring bath comprises- water,- at least one polar solvent and/or at least one non-polar solvent, and- an oxidizing agent or a reducing agent and/or a polar decoloring agent, wherein the decoloring bath has a pH about ≥ 8, and wherein the pH of the decoloring bath is adjusted by adding a base, preferably NaOH or wherein the decoloring bath has a pH about ≤ 6, and wherein the pH of the decoloring bath is adjusted by adding an acid, preferably HCl.