In the realm of textile coating and finishing, the past year has seen a surge in patent families related to various advancements. Some of the most common patents were for antibacterial textiles, textiles with odor control features, and artificial leather. The inventions primarily focused on apparel and automotive applications. Moreover, there was a notable emphasis on environmentally friendly manufacturing processes, such as non-fossil based alternatives and natural leather derived from non-animal sources. Additionally, this selection of patents also encompassed innovations in fluorine-free solutions for liquid repellency, anti-fouling treatment of textiles, light-sensitive outdoor textiles, and a flexible heat exchange element.

Fluorine-free durable water repellent compositions

Patent number: EP4293062

Publication date: 2023-12-20

Applicant(s): SWISS PERFORMANCE CHEMICALS AG

Inventor(s): RUSHFORTH MIKE; FOESSEL MATTHIAS

Motivation

The application of durable water repellent (DWR) treatments to fabrics is a process widely used in the textile industry for the production of high-performance outdoor clothing, outdoor equipment and protective clothing. Broadly speaking they can be divided in fluorocarbon (FC) DWR systems and non-fluorine DWR systems. However, it has been recognized that low molecular weight impurities associated with the fluoropolymer have serious health implications. Therefore, there is a need for improved non-fluorine DWR systems. Particularly, such systems should aim for the performance of FC-DWR systems but avoid health implications and / or environmental implications. Additionally, it would be beneficial if such systems can be used with machinery already available, thereby facilitating a switch to such new systems.

Summary

The invention thus provides (i) impregnating dispersions suitable to obtain a durable water repellent effect on fabrics and fibrous substrates; (ii) a concentrate dispersion and a kit of parts to prepare the above impregnating dispersions; (iii) textile products having a durable water repellent properties; (iv) methods for manufacturing impregnating dispersions, concentrate dispersions, and kit of parts; and (v) methods for manufacturing textile products having a durable water repellent effect. The methods described herein prove to be environmentally friendly and allow the use of renewable starting materials. Specifically, impregnating dispersions, concentrate dispersions, corresponding kit of parts are disclosed, each comprising candelilla wax and a blocked isocyanate selected from the group of blocked-isocyanates having a molecular weight of below 2000 g/mol. The invention further provides for novel methods to prepare concentrate dispersions, impregnating dispersions and treatment of fabrics. The fabrics treated with the inventive impregnating dispersions show unexpected beneficial properties, when compared to known treatments. These beneficial properties include improved water repellency, even after multiple washing cycles and for a wide variety of fabrics. The thus obtained fabrics are applicable in a wide variety of applications, including outdoor clothing and protective clothing.

Process for preparing a multi-layered composite suitable for making polyurethane synthetic leather

Patent number: WO2023149799

Publication date: 2023-08-10

Applicant(s): STAHL INTERNATIONAL B.V.

Inventor(s): TIMMERMANS HENRICUS CORMELIS MARIA; CAPPOZZO ROBERTO

Motivation

Artificial leather also called imitation leather or synthetic leather, or leatherette or PU leather provides an economic and multifunctional way to replace natural leather. However, its production often evolves solvents such as DMF. For many years, especially in the field of coatings, the trend has increasingly been moving away from solvent-based systems towards solvent- free high solids systems and, in particular aqueous systems because of the ecological advantages thereof. Water based (WB) coagulation also called salt, acid or electrolyte coagulation is an environmentally friendly alternative to solvent-based processes for artificial leather.

Summary

The object of the present invention consists in providing a novel process for producing a multi-layered composite provided with at least one polyurethane microporous layer obtained by aqueous coagulation which enables products of high quality to be achieved in a simple process. In particular the obtained multi-layered composites are highly porous, highly breathable, open, highly resilient, elastic and flexible structures that makes them very suitable as base material for artificial leather. Another important advantage of this water-based coagulation procedure is the absence of DMF traces in the final article. The present invention provides a process for producing a multilayered composite comprising at least a support layer provided with at least one microporous layer based on polyurethane comprising the following steps: (i) providing a polyurethane formulation containing one or more aqueous polyurethane dispersion and optional additives; (ii) foaming said polyurethane formulation; (iii) providing a support layer; (iv) treating the support layer with an aqueous coagulation solution and optionally removing excess coagulation liquid; (v) coating the foamed polyurethane formulation obtained in step (ii) onto a surface of the treated support layer obtained in step (iv); (vi) treating the coated support layer obtained in step (v) in an aqueous coagulation bath;(vii) optionally removing, preferably mechanically removing, excess coagulation liquid, for example, by squeezing the coagulated foamed polyurethane layer obtained in step (vi); (viii) drying the coagulated foamed polyurethane layer; (ix) optionally washing the dried composite obtained in step (viii) with water and drying again, wherein no extra drying step is carried out between step (iv) and step (v).

Odor control polymer coatings on textiles

Patent number: WO2023225395

Publication date: 2023-11-23

Applicant(s): MICROBAN PRODUCTS COMPANY

Inventor(s): LI YIHONG; ONG IVAN; FEI XIUZHU

Motivation

Current major odor control technologies on textiles are through adsorption of odorants by common adsorbents, such as activated carbon, zeolites, and some heavy metal containing actives. Heavy metal products are a cause for environmental and regulatory concern to not only regulators but also consumers. The color fastness is often reduced to some extent when these heavy metal containing compositions are used.

Summary

This invention provides a solution for odor control through adsorption on a textile while meeting evolving requirements of heavy metal-free formulations and eliminating the use of fine particles to impart good hand and good color fastness to the textiles. In an aspect of the invention, an odor control composition is provided comprising an effective amount of sodium pyrithione to reduce odor on a textile and an effective amount of binder to coat the textile. Sodium pyrithione is a particle-free, heavy metal-free, water-soluble compound. Sodium pyrithione is a moderately alkaline chemical in nature such that it can be utilized to neutralize acidic odorants, such as isovaleric acid and acetic acid, which are common body odorants. The binder is a polymeric binder, and is preferably selected from the group consisting of a polyacrylic binder, a polyurethane binder, and a combination thereof. The composition may further contain a softener. The softener is selected from the group consisting of a sulphated fatty alcohol, anionic fatty acid polysiloxane, nonionic fatty acid polysiloxane, ethoxylated polysiloxane, polyethylene based softener, and a combination thereof.

Net for fish farming, method of making and use thereof

Patent number: WO2023036491

Publication date: 2023-03-16

Applicant(s): DSM IP ASSETS. B.V.

Inventor(s): SCHNEIDERS HANS; TACKEN BART; ROOZEMOND PETER

Motivation

Although various aquaculture nets have been proposed or described in literature, there is still a need for a fishing or fish farming net that shows little fouling in sea or fresh water, which net can be efficiently cleaned with a waterjet or in an aquaculture drum washer, and which has good retention of net mesh strength and net dimensions upon cleaning.

Summary

The present invention relates to a net which net comprises at least one cord (75, 175), said cord forming net meshes and comprising an anti-fouling coating (76, 176), wherein the at least one cord comprises at least one composite strand (73, 173a, b, c) comprising high-performance polyolefin fibers (72, 172), and a polymer composition (70, 170). Said polymer composition comprising a copolymer comprising ethylene units and having a peak melting temperature measured according to ASTM E794-06 of 40-140 °C. The anti-fouling coating has been applied on the net and comprises an oligomeric or polymeric binder and at least one anti-fouling agent. Such net with two different coatings present at different levels of the net construction, shows an advantageous combination properties, making the net very suited for use in fishing or in fish farming. A specific advantage of the net according to this disclosure is that it shows better retention of mesh breaking strength and/or dimensions after cleaning in an industrial tumbler washer. The disclosure also relates to a method of making a net having anti-fouling properties, to use of the net according to present disclosure for fishing or in fish farming, and to a fish farm construction, like a fish cage for use in open water, comprising the net according to present disclosure.

Composition for the impregnation of textile materials, composite textile materials comprising such a composition, and a process for obtaining them

Patent number: EP4299829

Publication date: 2024-01-03

Applicant(s): Industrie Chimiche Forestali S.p.A.

Inventor(s): BOZZATO EMILIANO; TAGLIETTI MARCELLO; CAMI GUIDO; GATTO EMANUELA; MALVISI LUCA

Motivation

In recent years, the need has been increasingly perceived to lower the environmental impact of industrial production processes, and thus of the products resulting therefrom. Thus, there is a need for processes with low environmental impact, significantly reducing the use of toxic, polluting substances and/or resulting from non-renewable sources.

Summary

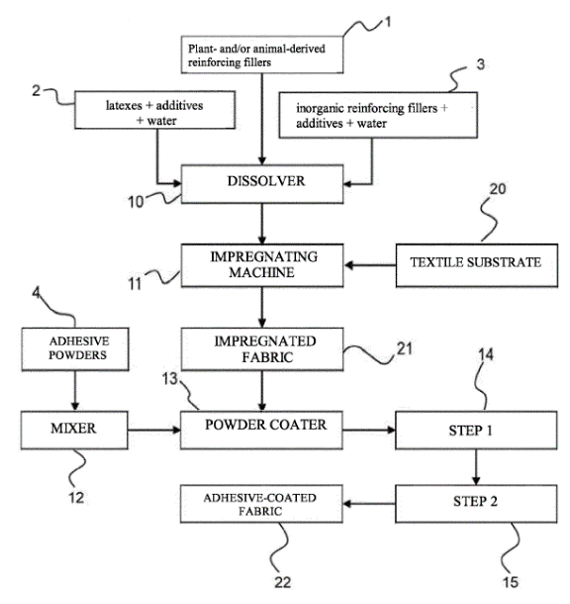

The present invention relates to an impregnating composition comprising plant- and/or animal-derived reinforcing fillers, thus from renewable sources, preferably resulting from production waste from the agri-food industry; a composite textile material impregnated with such a composition; and the process for the production thereof. The resulting composite materials have performance levels, both in terms of finishes and mechanical properties, which are not only comparable, but even better than those of the composite textile materials known in the art. Surprisingly, such performance levels are obtained against a decrease in the overall density of the composite textile materials according to the present invention, compared to those known in the art for which the use of greater amounts of raw materials is necessary for the preparation of the finished products. Hence, the composite materials according to the present invention allow not only the recycling of materials that would otherwise be considered waste, but also a reduction in the use of raw materials. The present invention relates to: (i) an aqueous elastomeric composition, for the impregnation of textile materials, comprising at least one latex, at least one dispersant, at least one plant- and/or animal-derived reinforcing filler, and water; (ii) an aqueous elastomeric composition also comprising at least one emulsifier; (iii) a process for the production of a composite textile material, comprising the following steps: (a) preparing an aqueous elastomeric composition comprising at least one latex, at least one dispersant, at least one plant- and/or animal-derived reinforcing filler, and water; (b) Soaking a textile substrate in the composition obtained in step a); (c) Pressing the impregnated textile substrate; (d) Drying the textile substrate obtained in step c); and (e) Calendering the dry textile substrate. Finally, the present invention relates to a composite textile material obtainable through the process according to the present invention.

Antibacterial object and method of manufacturing the same

Patent number: EP4201204

Publication date: 2023-06-28

Applicant(s): ATOMOS MASTER KEY GMBH

Inventor(s): HÜTHER FABIO

Motivation

Pathogenic germs such as bacteria or viruses increasingly endanger the health of humans and animals. The destruction and/or prevention of the spread of germs is of great importance not only in the treatment of water. Suitable measures for improving hygiene are also required in many other fields, in particular in hospitals, in gastro-operations and in the food industry. In this case, it is often not possible to install a device with electrical energy supply for killing germs, as in the case of water treatment.

Summary

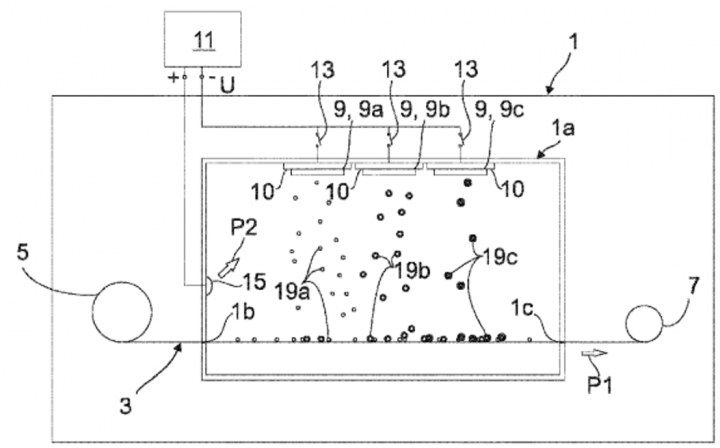

It is an object of the present invention to provide an object or a device which has an antibacterial effect without the supply of electrical energy, and to provide a method for the production thereof. This object is achieved by an object provided with an antibacterial finish and by a process for its production. Objects comprising an electrically non-conductive substrate are rendered antibacterial by coating the substrate by sputtering particles of titanium and at least one further metal in such a way that the coated particles are arranged in different combinations as clusters on the substrate, wherein the particles within the clusters are electrically conductively connected to one another, and wherein the clusters are arranged on the substrate at an island-like distance from one another and electrically insulated from one another. Depending on the intended use, the coated substrate itself, preferably a textile or non-textile fabric, can be used as an antibacterially finished object or antibacterially finished device. Thus, for example, nonwovens or textiles coated in the manner mentioned can be used as cleaning cloths having an antibacterial action or, in the medical sector, as antiseptic substrates or packs. Antibacterially treated substrates can also be designed as components of corresponding devices or objects. Examples of such objects are water filters, air filters, protective masks, wound dressings, garments, shoe inserts, etc., wherein at least one layer of the substrate is formed as a surface portion of the object or is embedded in the object.

A heat exchanging element

Patent number: EP4230941

Publication date: 2023-08-23

Applicant(s): TABET BENSLIMANE HASSAN

Inventor(s): TABET BENSLIMANE HASSAN

Motivation

Heat exchanging elements are known in the art. As an example the heat exchanging elements of a central heating system usually are metal radiators comprising water as heat exchanging fluid. This water is circulated from a heat source to the radiators and back to the heat source, optionally via a buffer tank. Disadvantage of these radiators is the inflexibility to provide radiators with dimensions adapted to the mounting space available in the building.

Summary

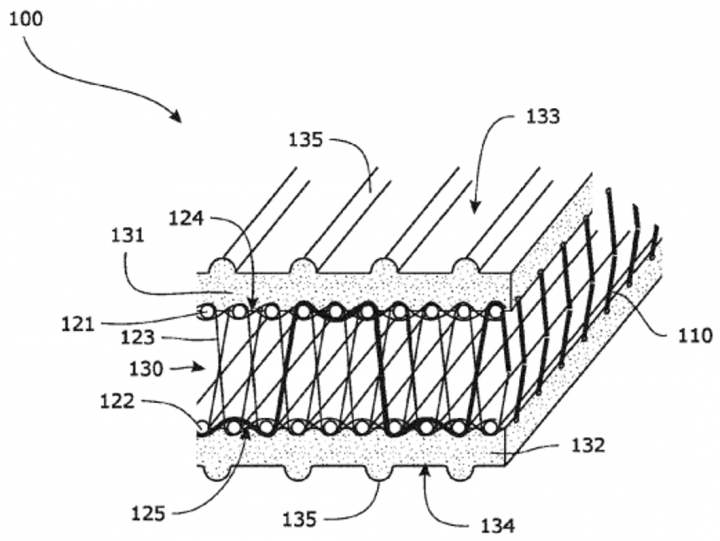

It is the object of the present invention to provide heat exchanging elements which (i) are bendable, or even flexible, preferably adapted to be mounted on non-planar surfaces; (ii) have an increased thermal performance, (iii) have a more uniform heat distribution over the surface of the heat exchanging element. According to a first aspect of the invention, a heat exchanging element is provided, the heat exchanging element comprising a first and a second textile layer, the textile layers being spaced one from the other. The outer side of the first textile layer is coated with a first liquid-tight polymeric coating, this first liquid-tight polymeric coating comprises thermally conductive particles. The outer side of the polymeric coating is the side of the coating not in contact with the first or second textile layer. The first and second textile layer each have an outer and an inner side. The inner sides of the two textile layers face each other and are spaced one from the other. Between the two textile layers, a space or volume is provided, which space or volume is adapted to receive and allow to pass heat exchanging fluid, like heat exchanging liquid between the two textile layers. Preferably the outer side of the first liquid-tight polymeric coating is uneven or profiled, i.e. the specific surface per surface area unit of the outer side of the first liquid-tight polymeric coating is more than 1 m2/m2, such as more than 1,01 m2/m2.

Omni-spectral camouflage and thermoregulation composition

Patent number: US11774652

Publication date: 2023-10-03

Applicant(s): STEALTH LABS LLC

Inventor(s): HERTEL MARC

Motivation

The protection and survival of troops on the battlefield is a vital aspect of conducting combat operations. Thermal camouflage is one of the most effective ways to increase the protection and survival of troops in what is becoming peer-to-peer level potential conflicts. Thermal camouflage is a method for assimilating into the environment in response to an interrogation wavelength of a detector which may correspond to visible, infrared (IR), and microwave wavelengths. The rapid development of reconnaissance measures, detection, and targeting technologies hinder the ability of troops to operate in a wide spectrum of electromagnetic radiation. It is becoming increasingly necessary to continually advance the effectiveness of various means of thermal camouflage on clothing, in garments, in shelters, sleep systems, camouflage nets and more.

Summary

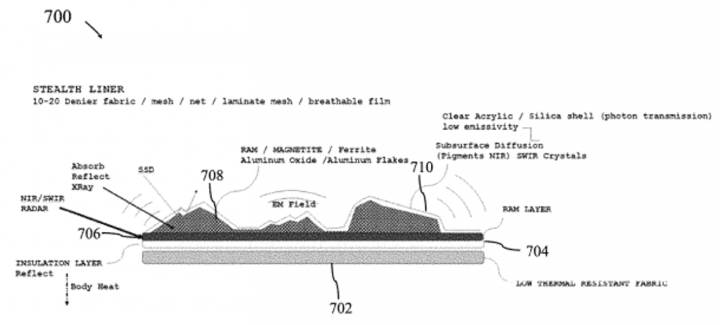

Exemplary embodiments of the present disclosure provide a system, apparatus, and methods for producing a high-performance camouflage and thermal management composite fabric textile systems. The systems comprise woven and non-woven composite fabrics consisting of layers for thermal and electromagnetic wave propagation as well as human thermal emission control. The systems incorporate thermal plastic insulation, felt insulation, electromagnetic wave absorption materials, electromagnetic wave propagation and thermal emission control elements, and camouflage pigment patterns. Dots containing encapsulated metallic particulates enable omni-spectral electromagnetic wave and thermal radiation signature manipulation and control as well as cost-effective manufacturing. Single blended textile processed via needle punching produces hair/fur-like protrusions made from a multilayer fabric composition having EM wave and thermal radiation control elements. The protrusions subsequently contain EM propagation and thermal emission control elements on their surfaces for omni-spectral camouflage and detection mitigation. The systems expand the options for meeting the demands of today and future stealth missions.