There is a growing demand for functionalised textiles and coatings with antimicrobial properties for health, hygiene, odour and durability reasons.

Antimicrobial solutions are available, but they pose toxicity problems both for humans (cancer, endocrine disruption) and for the environment (accumulation in the environment, toxicity to flora and fauna).

In recent years, more and more consumers have become aware of these problems and are in favour of reducing the use of harmful products in order to reduce human impact on the environment. This growing environmental awareness is forcing chemical manufacturers, distributors and users to make the transition to non-toxic, bio-based materials. Unfortunately, current alternatives for controlling microorganisms in an environmentally responsible manner are still inadequate. A new approach that meets these needs is therefore essential to prevent the damage caused by microbial contamination while respecting the environment.

The MicroEcoTex project is part of this approach, proposing an effective antimicrobial solution based on eco-responsible materials.

Objectives and approach

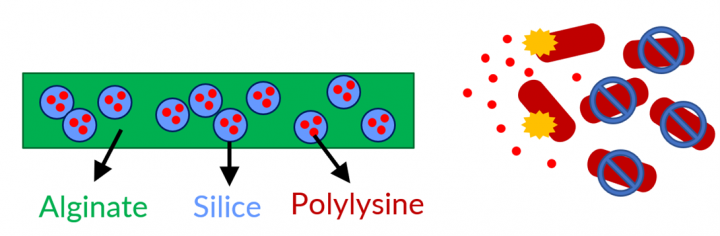

To this end, the MicroEcoTex project aims to produce antimicrobial textiles and coatings for medical applications (burns and wound treatment) and agri-food applications (food preservation and/or packaging). The technology is based on the encapsulation of an antimicrobial agent in the material. Once in place, this agent is released to eliminate bacteria and viruses that come into contact with the material.

In our case study, these textiles and coatings are developed from a silica-alginate composite containing polylysine, a naturally occurring antimicrobial agent used in the medical and agri-food sectors, which is released in a controlled and sustained manner over several days/weeks.

Silica and alginate were chosen for their acceptance in the medical and agri-food sectors, safety, biodegradability and control of the release of the molecules.