Closing events

As the MultiCycle project enters its final stages, we are pleased to invite you to two dissemination events showcasing and celebrating the progress made since 2018 in demonstrating the circular economy in action in obtaining high quality, value-added single polymer recyclates from challenging end of life plastics multi-materials.

- On 10th March, the online event "Shifting Towards Circular Economics in Thermoplastic Composites" will cover integration and demonstration of key technologies and industrial case studies dealing with thermoplastic composites in the automotive sector.

- On the 7th April, our final dissemination event "Demonstrating the Circular Economy in Plastic Multimaterials" will be held in Ghent, Belgium where the focus will be primarily on the significant steps forward made in selective polymer recovery from flexible multilayer films used in packaging and on how these have performed when evaluated back in the value chains from which they arose.

Full details on both events and details of how to register free

Context

In line with the Plastic Strategy for Europe, the time has come to stop depletion, landfilling and incineration and to shift to a Circular Model in the plastic sector improving the recycling rate but also the value of secondary raw materials from plastic recycling.

As such, MultiCycle will deliver an industrial recycling pilot plant for fossil and bio-based thermoplastic multilayer packaging and fibre reinforced composites using a novel solvent based selective extraction process which allows recovering pure plastics and additives in mixed wastes for their later reprocessing into value-added applications.

Inspired by the Circular Economy ethos, the overriding goal of MultiCycle is to deliver an innovative recycling pilot plant and demonstrate that the resulting processes are economically & environmentally sustainable for valorising currently non-recyclable materials (multilayer packages and composites).

The project will combine several approaches to optimise the material recycling: i) recycling and reprocessing upscaling in an industrial environment, ii) advanced monitoring and PAT solutions, iii) demonstration of recovered materials’ potential for packaging and automotive applications.

By overcoming the challenges linked to multi-materials recycling, setting up the initial value chains, raising industry acceptance and demand for more sustainable materials, MultiCycle will have enduring impacts for significantly reduced landfill and environmental impact as well as increased consumer satisfaction.

Objectives

MultiCycle will develop a tailored sustainable process approach to recycle thermoplastic-based multi-materials to enable their use in multiple life cycles.

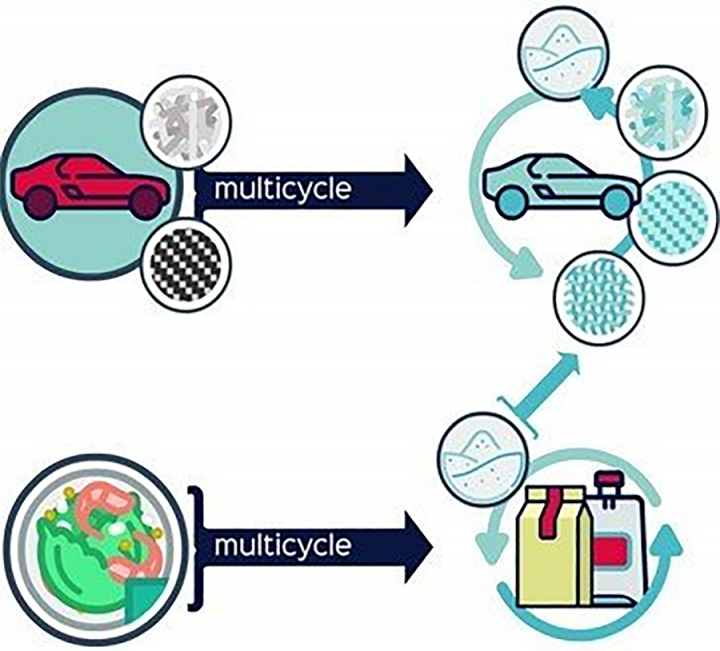

The process, applicable to virtually any plastic or composite material, will be demonstrated in two main large volume applications:

- Multilayer packaging including PET, PE, PP and barrier layers (such as EVOH, PA,metallised films and flexible films that as yet may not be recycled in a cost-effective way. This accounts for around 50% of plastic packaging, or ca. 10 mio tons/year in EU.

- Fibre reinforced thermoplastics (FRP) (based on PA12 or PP matrix, long glass or carbon fibres). Plastic parts constitute about 16% of EU End-of-Life Vehicles (ELVs) wastes,or ca. 1 mio tons/y

MultiCycle will deliver an industrial recycling pilot plant for fossil and bio-based thermoplastic multilayer packaging and fibre reinforced composites using a novel solvent based selective extraction process which allows recovering pure plastics and additives in mixed wastes for their later reprocessing into value-added applications.

Multicycle Newsletter

Consortium

Press corner

Brussels, 28th November 2018

The MultiCycle project held a successful kick-off meeting in Brussels on 28th November. This new three-year EC Horizon 2020 Innovation Action will deliver an industrial recycling pilot plant for thermoplastic-based multi-materials allowing selective recovery of pure plastics and fibres from mixed wastes without downgrading as a key enabling step towards the realization of a circular plastics economy.

Acknowledgments

H2020 – SPIRE

Horizon 2020 is the biggest EU R&D programme ever with nearly €80 billion of funding available over 7 years (2014 to 2020). It brings breakthroughs, discoveries and world-firsts by taking great ideas from the lab to the market. MultiCycle is funded under CE-SPIRE-10-2018- Efficient recycling processes for plastic containing materials.

A.SPIRE is the European Association which is committed to manage and implement the SPIRE Public-Private Partnership. It represents innovative process industries, 20% of the total European manufacturing sector in employment and turnover, and more than 130 industrial and research process stakeholders from over a dozen countries spread throughout Europe. SPIRE brings together cement, ceramics, chemicals, engineering, minerals and ores, non-ferrous metals, steel and water sectors, several being world-leading sectors operating from Europe. The mission of A.SPIRE is to ensure the development of enabling technologies and best practices along all the stages of large scale existing value chain productions that will contribute to a resource efficient process industry.

MultiCycle is inline with the SPIRE roadmap and will deliver substantial impacts for a more sustainable plastic processing industry.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 820695