Bacground

The project will screen the application possibilities and preferred processing conditions of polybutylene succinate (a biobased polymer) in textile applications.

As the properties of polybutylene succinate approach the ones of polypropylene, a short development track for end applications is foreseen.

In recent years we have witnessed a significant progress in the development of polymers from renewable resources with a similar processability and functionality as conventional polymer materials. Several biobased polymer types have been developed, each having its own limitations. Polybutylene succinate (PBS) is a biobased polymer with properties comparable to polyolefins. PBS is therefore a material complementary to other existing biobased polymers and is expected to become an important source of biobased material in the coming years.

Goals

The main goal of the project is to screen the use of fully biobased PBS in fibre melt extrusion applications and to demonstrate to the industry its applicability in the selected end products. The project will result in a selection of polymer grades suitable for fibre formation, optimisation of polymer formulation via adding functionalization and processing additives, guidelines per end application in which high-quality fibres can be produced, and the determination of maximum mechanical performance of the end products that can be obtained.

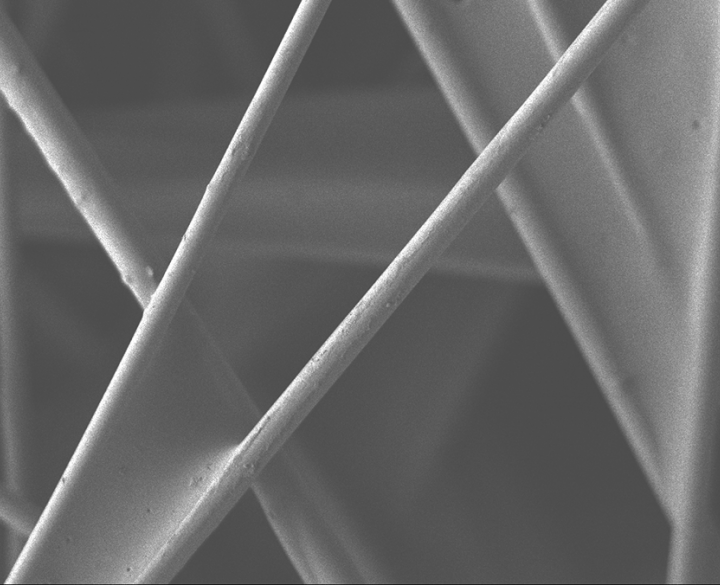

The processing window for a range of processes i.e. POY/FDY/BCF multifilament yarn spinning, monofilament and tape extrusion will be developed. The produced textile fabrics will be characterized for relevant properties like dyeability, biodegradation under various conditions (long term durability or compostability, depending on application), tensile strength and elongation, dimensional stability, stability against illumination, heat and moisture.

Because of the properties of PBS, especially a substitution of polypropylene is expected. Short term applications are foreseen in agrotextiles, interior textiles or hygiene products.