Abrasion-resistant gloves must be used as personal protective equipment (PPE) in any environment where workers face a significant exposure to abrasive material.

EN 420 - Occupational Protective Gloves, General Requirements - defines the requirements for all protective gloves (except electrical and medical gloves) for glove construction, cleaning, comfort and efficiency, marking and information.

Principle

Circular specimens of material are abraded under known pressure with a cyclic planar motion in the form of a Lissajous figure which is the result of the simple harmonic motions at right angles to each other. The resistance to abrasion is measured by the number of cycles required for breakthrough to occur.

Example of a lissajous curve or figure, a mathematical graph of a system of parametric equations describing a complex harmonic motion.

Testing procedure

The test is carried out by using an abrasion machine (Martindale Wear and Abrasion).

Pressure on specimen: (9,0 ± 0,2) kPa.

Samples

Four test specimens shall be taken from four individual gloves of the same glove series.

In case of an irregular design of the palm, the test specimen shall be taken in the area where the least protection is expected (remove the reinforcements that do not cover the whole palm).

Where the test specimen is made of several unbounded layers, the test is performed on each layer. When the specimen is made of bonded layers if the layers can be separated without damaging the material, the test must be performed on each layer independently. Otherwise, the test must be performed on all layers, taking care not to have a seam in the test area.

Test results

The performance of the sample is determined by the specimen breakthrough, which is the visually observed deterioration in a specimen after exposure to a specified number of abrasion cycles, i.e.:

- in woven fabrics, when two separate threads are completely broken, resulting in a hole to appear

- in knitted fabrics, when one thread is completely broken, resulting in a hole to appear

- in bonded layers, when the diameter of the first hole through all layers resulting from ≥ 1 mm

- in all other materials, when the diameter of the first hole resulting from the wear ≥ 1 mm

Marking

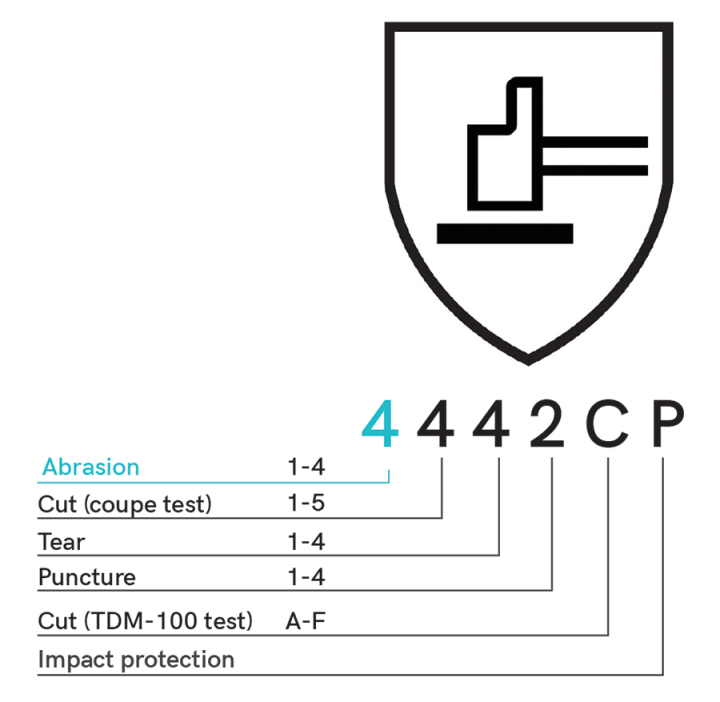

The performance level (1-4) is displayed in first (most left) position underneath the pictogram.

Send your samples to

Centexbel - Physical lab

Technologiepark 70

9052 Gent-Zwijnaarde

Belgium

+32 9 220 41 51

gent@centexbel.be