Polymer composites are made from a textile reinforcement in a polymer matrix. Centexbel-VKC dispose of the adequate equipment and expertise to perform detailed analyses of fibre reinforced composites and the materials they are are made from.

Thermal behaviour and rheology

The melting and crystallisation behaviour of the thermoplastic matrix is characterised by means of differential scanning analysis (DSC). Rheology studies the flow behaviour of the thermoplastic during melting. These analyses allow us to predict the impregnation quality of the composites. Several tests are useful for this purpose, including Melt Flow Index (MFI), rotational and capillary viscometry, viscometry according to Ubbelohde, etc. The (M)DSC method is used to map the curing reactions of thermoset matrices.

Mechanical behaviour

The static mechanical properties (rigidity, resistance to elongation at break) of composites are characterised by traction, flexion and compression tests. The impact resistance is also a very important parameter of composites. The impact resistance is measured by means of the choc resistance tests Charpy or Izod that register the amount of energy that is absorbed by a material at break. However, the behaviour at break of composites is often a complex phenomenon in contrast to metals or plastics where a unilateral behaviour at break in traction occurs at the height of the slot. The three standard break modes - traction, compression and shear - may indeed occur in one and the same sample.

Therefore, it is hard to associate the absorbed energy that has been registered to a specific structural component, and the impact drop test is generally more adequate to characterise fibre reinforced composites. In this test, the sample is submitted to an impact with a prescribed impact energy. The compression after the impact or flexion is then evaluated. This procedure allows quantifying the drop in resistance and rigidity caused by the impact.

Creep is the tendency of a material to deform when submitted to a constant (prolonged) load. Creep is in general an undesirable phenomenon that may limit the lifespan of an object. Temperature also influences the creep behaviour of materials. The more the temperature rises, the quicker creep occurs.

Centexbel evaluates creep in traction, compression and flexion at temperatures ranging between ambient and 150 °C.

volumetric fraction of fibres

The volumetric fraction of fibres of a composite is evaluated in several ways. The methods are either destructive or non-destructive. Please note that the results of destructive methods are more precise. Centexbel usually carries out destructive test methods, where the matrix is chemically or thermally removed. The matrix is burnt by TGA (thermogravimetric analysis) or by the so-called “Resin bur-off test” in the case of ceramic fibre reinforced samples.

In the case of the TGA technique, the samples are very small resulting into a relatively large margin of error because of local differences in the composite. Anyway, the TGA technique has the advantage that it can be used for glass fibre and carbon fibre reinforced composites. In the latter case, the TGA test is performed under an azotic atmosphere. The Resin Burn-off test is used for larger samples allowing for local differences.

Burning behaviour

The burning behaviour of composites is another important parameter. In its large burning behaviour laboratory, Centexbel performs several tests to quantify the flame retardant properties of composites.

thermo-mechanical properties

Thermo- mechanical measuring techniques offer the opportunity to study the influence of temperature on mechanical properties. These tests are very useful for materials that will be applied in hot environments. The simplest analysis is the Heat Deflection temperature (HDT) that measures the temperatures at which the material deforms when submitted to a specific load. The test indicates the resistance to deformation at high temperature. It is also possible to measure the Vicat temperature. During this test, the material is being locally deformed by means of a needle at a constantly rising temperature. Thermo-mechanical analyses (TMA) and dynamic thermo-mechanical analyses (DTMA) are more precise and accurate methods. TMA measures the dimensional changes under a rising temperature or under a constant high temperature. TMA also performs a precise control of the (static) force applied on the sample. Thanks to the different modes of this technique, TMA determines several characteristics, including free crimp or crimp force, the relationship between tension-deformation, shear temperature under load, thermal dilatation coefficient, etc.

In the case of DTMA, an oscillating force is applied by moving clamps during a heating and a cooling phase. This technique determines the viscoelastic properties of the sample in relation to temperature, i.e. the elasticity and viscosity module and the damping factor in relation to temperature, frequency and time. The DTMA method determines small transition domains, such as bridging glass transitions that cannot be detected by the DSC method. DTMA also determines in an easy way the relaxation behaviour, the flow and the maximum processing temperature. Centexbel and VKC-Centexbel dispose of a single- or dual-cantilever clamp, three-point flexion and traction modus.

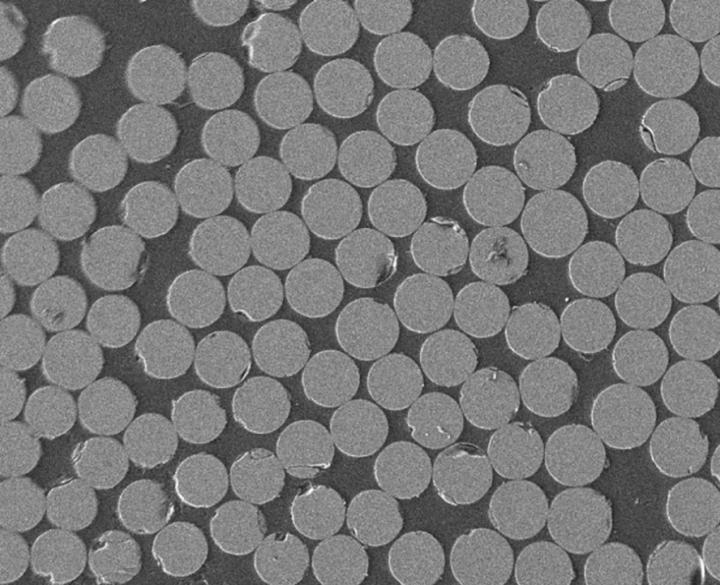

Microscopy

In the case of composites, microscopy is often used as a complementary technique to clarify certain observations from other analyses, for example to evaluate the impregnation quality of a certain procedure, or to study the surface of a break. According to the needs, the laboratory opts for an optical or an electronic microscope.

Send your samples to

Centexbel - VKC

Etienne Sabbelaan 49

8500 Kortrijk

Belgium

+32 56 29 27 00

info@vkc.be