Principle

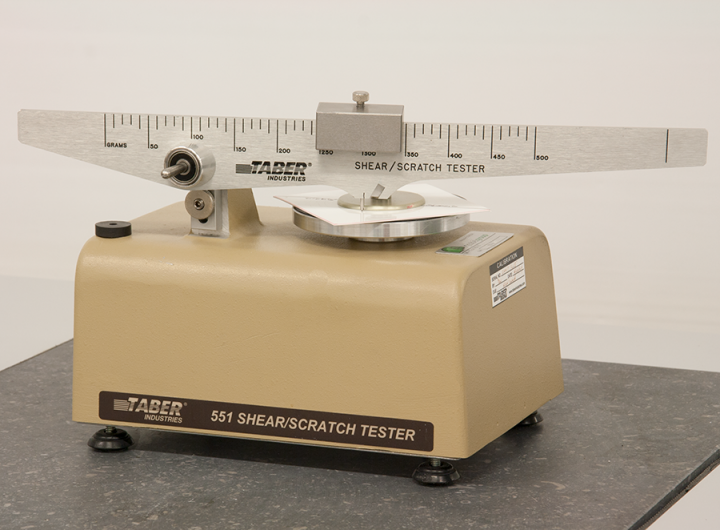

The Taber shear/scratch tester provides a good view on the resistance to shear, scratching, carving, scraping or engraving of materials.

The test can be performed on a large variety of flat and hard materials and can also be applied to determine the homogeneity of materials as well as the adhesion of protective films and the effects of ageing.

Testing procedure

The test is performed on samples with a maximum dimension of 150 x 150 mm and a maximum thickness of 12,7 mm.

- The samples are placed on a rotating table and the predetermined cutting tools are placed on the sample. The applied forces vary from 0 to 1000Gr. In general, a lower weight is applied at the beginning and is then gradually raised until visual damages occur on the sample surface.

- The table rotates at a constant speed of 5 rpm. This constant speed allows a higher accuracy of the test results.

After testing a simple visual inspection is done or by means of a microscope.

Testing applications

- Determination of the resistance to shear

- Determination of scratch resistance

- Determination of adhesion of coatings

Video © TABER® Industries

Send your samples to

Centexbel-VKC

Etienne Sabbelaan 49

8500 Kortrijk

Belgium

+32 56 29 27 00

info@vkc.be