The comfort of textiles and garments is the result of both psychological aspects (design, fit, quality, aesthetics) and physiological aspects, including thermophysiological and sensorial (softness, suppleness) comfort. Thermophysiological comfort is the result of the heat and moisture transfer through the textile that will regulate the body’s temperature, and is an important feature in clothing and especially in sportswear and professional (protective) clothing.

Centexbel determines the thermal insulation (expressed in Rct) and water vapour permeability (Ret), as well as the moisture management of fabrics and garments.

Skin model

The skin model or sweating guarded-hotplate is designed to obtain precise measuring data on the heat and moisture transmission through a flat (single layer) woven or nonwoven fabric and simulates the heat and moister transfer taking place in the approximity of the human skin. The test method is described in ISO 11092.

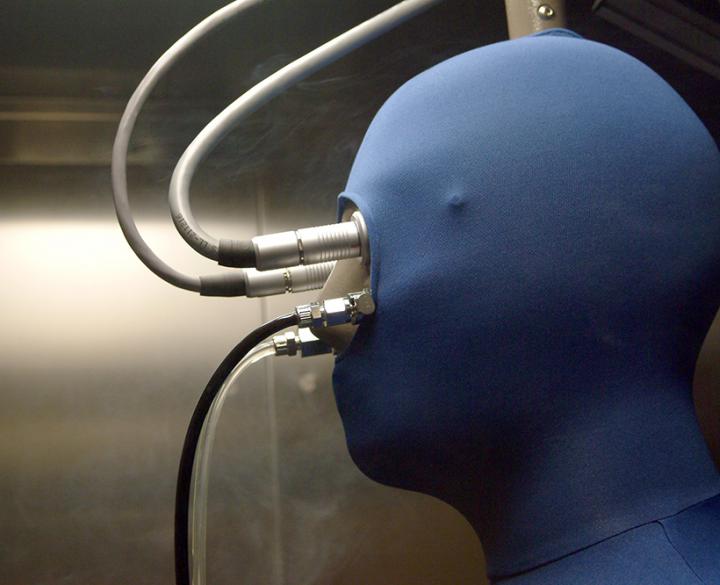

Newton, thermal and sweating manikin

Using the thermal, sweating and moving manikin we can predict the thermophysiological comfort of an entire garment (or parts) in real use conditions. The “Newton” manekin is composed of a thermally conductive carbon fibre-expoxy shell with incorporated thermal resistors and sensors.

Thermal features

- thermally conductive Carbon Fiber-Epoxy shell

- standard garment size M

- 26 independent thermal zones

- distributed heating wires and wire sensors for accurate control and measurement of skin temperature to +/- 0.1°C

- water compliant for use with wetted skin

- standard joints at the shoulders, hips, knees, elbows, and ankles

- mannequin walking mechanism (speed variable from 0 to 55 double steps per minute : about 70 meters/min)

Sweating mechanism

- volumetric control of delivered sweat rate, selectable by mannequin region

- network of pores over the mannequin's surface

- removable fabric skin layer for water distribution by wicking

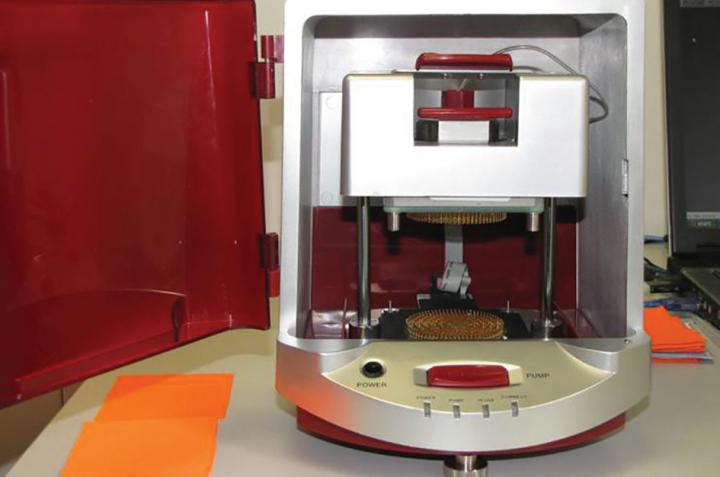

Moisture Management Tester (MMT)

To measure the dynamic liquid transport properties, a a sample is placed horizontally in the instrument between the upper and lower sensors.

These sensors are made of concentric rings of pins. A solution, representing perspiration, is dropped on the center of the upper face (skin side) of the test sample.

As the solution moves through and across the sample, the changes in electrical resistance are measured and recorded.

Send you samples to

Centexbel - Physical Lab

Rue du Travail 5

4460 Grâce-Hollogne

Belgium

+32 4 296 82 00

g-h@centexbel.be