Technical textiles play a crucial role in solving various challenges across different industries. These textiles are specifically designed to address societal and industrial issues by incorporating advanced features through functionalization and surface modification. For instance, technical textiles can offer flame retardancy for firefighter suits, waterproofness for mattress protectors, and antimicrobial effects for face masks. One of the current challenges in the technical textile industry is achieving oil-repellency without the use of fluorine-based compounds.

This month's patent alert highlights recent innovations focusing on fluorine-free alternatives that provide oleophobic properties, with many of these alternatives being silicone-based.

Fluorine-free dynamic water repellents with oil-repellent properties, water-repellent articles, and methods of making the same

Patent number: EP4301795

Publication date: 2024-01-10

Applicant(s): 3M INNOVATIVE PROPERTIES COMPANY

Inventor(s): ELSBERND CHERYL L. S.; POKORNY RICHARD J.; AMB CHAD M.; UNTIEDT NICHOLAS L.

Background

Fluorochemicals have been widely used for more than fifty years as fabric treatments that provided durable stain release, oil and water repellency, and dynamic water repellency. However, due to environmental and health concerns, governmental agencies and nongovernmental organizations have lately been pushing the apparel market towards the use of fabric treatments that are produced with raw materials that do not contain fluorine. However, non-fluorinated fabric treatments developed to date have shown little or no ability to provide durable oil repellency. Consequently, there is a need for a fluorine-free dynamic water-repellent fabric treatment with even a minimal degree of oil repellency.

Summary

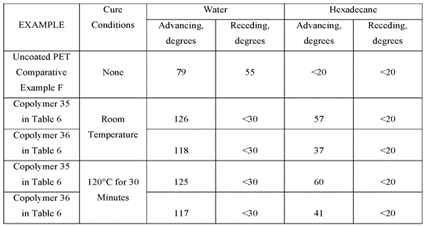

The present inventors have discovered through detailed study that a degree of oil repellency can be imparted to water-repellent silicone polymers by incorporating crystalline or rigid hydrophobic monomers. Without wishing to be bound by theory, the present inventors believe that methylated aromatic or cyclic monomers may tend to crystallize and orient to align the relatively lower surface energy methyl groups at the copolymer/air interface, thereby imparting a degree of oil-repellency. That is, the substrate is rated C or higher according to the AATCC Test Method 118-2013.

In one aspect, the present disclosure provides a copolymer preparable by copolymerization of monomer components comprising:

- at least one polydimethylsiloxane mono(meth)acrylate having a molecular weight of from 300 to 10000 grams/mole;

- optionally at least one C3-C10 carboxylic acid-functional mono(meth)acrylate or a salt thereof;

- at least one C5-C16 hydroxyalkyl mono(meth)acrylate; and

- at least one of: (i) at least one C10-C30 linear alkyl mono(meth)acrylate optionally having one or two carbon atoms replaced by O or S, with the proviso that no O—O, S—S, or S—O bonds are present; or (ii) at least one (meth)acrylate

Fluorine-free hydrophobic and oleophobic nonwoven

Patent number: WO2023232557

Publication date: 2023-12-07

Applicant(s): FIBERTEX NONWOVENS A/S

Inventor(s): BOBET PATRICE; KJELDSEN JONAS

Background

Nonwovens contribute to extend the lifetime of automotives and make them safer, more comfortable, more cost-effective and more sustainable. The combination of reducing the weight of the car, lowering fuel consumption, provide advanced insulation, advanced sound absorption, fire retardancy and resistance to water, fuel, extreme temperatures and abrasion, are usually only possible with a combination of a fluorine- containing compound and a nonwoven, namely a fluorinated nonwoven fabric. Fluorinated nonwoven fabrics protect the engine compartment and prevent liquid absorption, block leakage of resin and promote slip in moulding forms. Examples of usage for a fluorinated nonwoven fabric, in an automotive, are as motor insulation, battery cover, headliner and underbody.

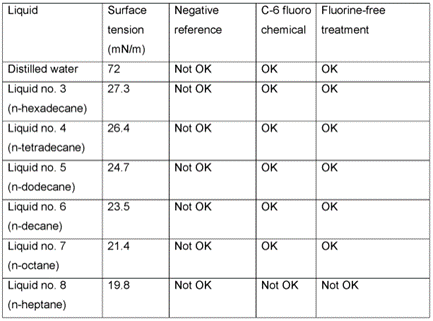

Summary

The solution proposed by the present invention comprises a method for making a nonwoven fabric having hydrophobic and oleophobic properties, the method comprising the following steps: providing a nonwoven fabric comprising fibers; providing an aqueous colloidal solution comprising nanoscale SiO2-particles, which is formed from an aqueous precursor solution comprising a SiO2-producing substance; and applying the colloidal solution onto the nonwoven fabric to form a hydrophobic and oleophobic finish on fibers of the fabric and thereby impart hydrophobic and oleophobic properties. A nonwoven fabric produced by such method comprises one or two surfaces having a hydrophobic and oleophobic properties, wherein the nonwoven fabric comprises fibers and wherein a hydrophobic and oleophobic finish is present on fibers of the fabric, including or especially those exposed to the surface, thereby imparting hydrophobic and oleophobic properties to the fabric in general and the surface in particular, wherein the finish comprises a continuous or interrupted porous SiO2-containing layer of nanoscale thickness. The colloidal solution comprises nanoscale colloidal SiO2 structures produced in a sol-gel process of the SiO2-producing substance.

Fluid resistant coatings for substrates

Patent number: WO2024009142

Publication date: 2024-01-11

Applicant(s): PLASMAGEAR INC.

Inventor(s): ROUT BISHAKH; JURCHUK SARAH; SAFAVIEH ROOZBEH; GIRARD-LAURIAULT PIERRE-LUC

Background

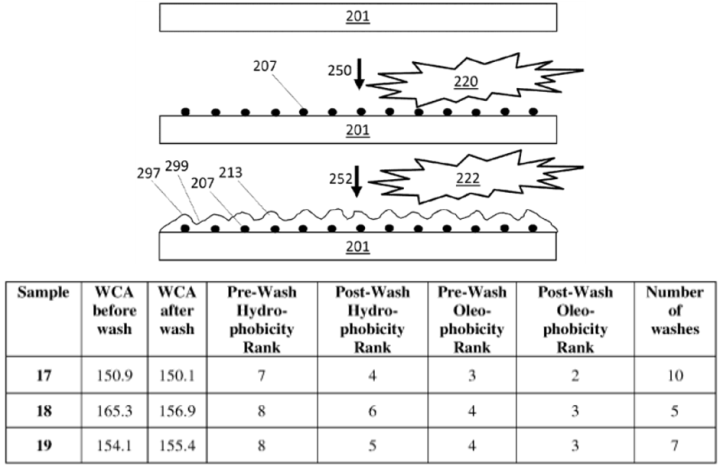

Articles comprising hydrophobic and/or oleophobic surfaces, and associated methods, are generally described. Hydrophobic and/or oleophobic surfaces have several important applications, including in the textile industry where there is high demand for water resistant and/or oil resistant textiles (e.g., for clothing, tents, etc.). The present disclosure is directed towards improved hydrophobic and/or oleophobic surfaces on substrates.

Summary

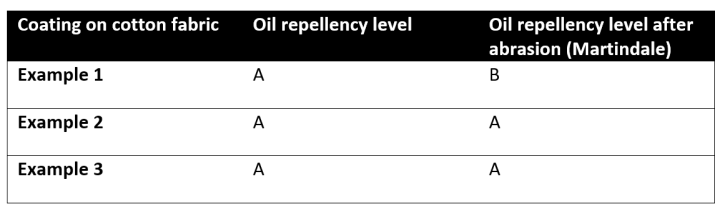

Articles that are oleophobic and/or hydrophobic, as well as associated methods, are generally provided. In some embodiments, articles described herein do not comprise fluorinated polymers. Articles described herein may comprise nanostructures that contribute to their hydrophobicity and/or their oleophobicity. Articles described herein may have high wash resistance. According to some embodiments, the article, comprises: a substrate comprising a surface, wherein the substrate comprises a textile; a plurality of nanostructures comprising a polymer on the surface of the substrate; and a layer comprising a polymerized silane and/or a polymerized siloxane, wherein the layer covers at least a portion of the surface and at least a portion of the plurality of nanostructures, and wherein a surface of the article is hydrophobic and/or oleophobic. According to some embodiments, the method of forming an article comprises: exposing a surface of a substrate to a plasma comprising a monomer; and producing a plurality of nanostructures on the surface without etching the surface, wherein the plurality of nanostructures comprises a polymerized silane and/or a polymerized siloxane, wherein the plurality of nanostructures comprises less than or equal to 0.5 at% fluorine atoms, and wherein a surface of the article is hydrophobic and/or oleophobic.

Fluorine-free three-proofing finishing agent with super-branch structure, preparation method and application thereof

Patent number: CN116377722

Publication date: 2023-07-04

Applicant(s): JIANGSU SUMEC LIGHT TEXTILE TECHNOLOGY INDUSTRY CO., LTD.

Inventor(s): FAN WENYE; SUN YONGXIANG; WANG HONGDA; CAI XIAOQING; ZHU JINXIU

Background

The three-proofing finishing agent for fabric is water-repellent, oil-repellent and antifouling finishing, which is to apply one or more finishing agents on the fabric to change the surface property of the fabric, so that the fabric is not easy to be wetted or stained by water and common greasy dirt. In general, to produce an oil-repellent effect in a polymer, it is often necessary to introduce hydrophilic functional groups such as sodium carboxylate salts, sodium sulfonate salts, and even polyethers into the polymer, but the introduction of these functional groups has a tendency to deteriorate the water-repellent effect of the polymer. Because the sodium carboxylate, sodium sulfonate and even polyether are not only hydrophilic, but also have relatively high polarity, a large amount of sodium carboxylate, sodium sulfonate and polyether often damage the film forming performance of the polymer on the surface of the fabric.

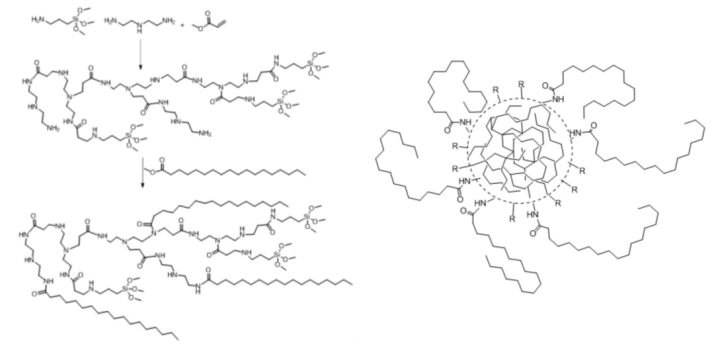

Summary

The invention discloses a fluorine-free three-proofing finishing agent with a super-branched structure as well as a preparation method and application of the fluorine-free three-proofing finishing agent. The fluorine-free three-proofing finishing agent with the super-branched structure comprises a polymer which is obtained by copolymerizing vinylamine, gamma-aminopropyltrialkoxysilane, acrylate and/or maleate; vinylamine groups on the surface of the polymer are bonded with stearoyl through-NH bonds. The polymer structure of the fluorine-free three-proofing finishing agent with the hyper-branched structure simultaneously contains water-repellent long-carbon-chain alkyl (octadecyl chain), siloxane chain segments, and oil-repellent amido and imino groups which are good in film-forming property, and the polymer simultaneously has water-repellent and oil-repellent structures, so that the fluorine-free three-proofing finishing agent with the hyper-branched structure can endow fabric with antifouling property.

Fluorine-free oil-proof textile fabric and preparation process thereof

Patent number: CN116657407

Publication date: 2023-08-29

Applicant(s): TECHNOLOGY (SHANGHAI) CO., LTD.

Inventor(s): YANG BAOJING; WANG TIANSHU

Background

The biological polymers such as polysaccharide, protein, fat and the like are paid attention to in the field of preparing fluorine-free oil-proof agents due to the characteristics of innocuity, harmlessness and biodegradability. The chitosan is excellent in oil resistance, nontoxic, harmless and biodegradable, but has high production cost, and can be applied and popularized due to the fact that the chitosan is dissolved under an acidic condition and can cause corrosion of coating equipment by acid. As a natural high polymer material, the soybean protein isolate has the protein content of more than 90 percent, has good film forming capability and low price, and is easy to obtain, so the soybean protein isolate is widely applied to the field of fluorine-free oil-proofing agents. However, isolated soy proteins have problems of poor mechanical properties and low water resistance due to strong intermolecular interactions of amino acids in their structures.

Summary

The invention relates to the technical field of oil-proof textile fabrics, and discloses a fluoride-free oil-proof textile fabric and a preparation process thereof. The preparation method comprises the following steps:

- blending and stirring cross-linked soybean soluble polysaccharide, sodium hexametaphosphate and soybean protein isolate to obtain a cross-linking agent;

- combining the mineralized nanocellulose and the long-chain alkyl functional aminated nanohybrid to obtain a supramolecular hybrid; ethyl alcohol is introduced into the soybean protein isolate, the supramolecular hybrid and mercaptoacetic acid are added and stirred, and an oil-proofing agent is obtained;

- compounding and stirring isophorone diisocyanate modified montmorillonite and soybean protein isolate to obtain a wear-resistant agent;

- sequentially coating the textile fabric with a cross-linking agent, an oil-proof agent and a wear-resistant agent, drying is conducted for 5-10 min at the temperature of 60-65°C after each time of coating, the textile fabric is placed in a hot press to be subjected to hot pressing after coating is completed, and the fluoride-free oil-proof textile fabric is obtained.

The oil-proof and water-proof performance is excellent (oil repellency tested according to GB/T19977-2014).

Procedure for obtaining water/oil repellent fabrics and/or leathers and related product thus obtained

Method of treating substrate

Patent number: US11932712

Publication date: 2024-03-19

Applicant(s): DAIKIN INDUSTRIES, LTD.

Inventor(s): NAKAMURA HISAKO; MATSUDA MICHIO; SAKASHITA HIROTOSHI

Background

Conventionally, fluorine-containing water repellent and oil-repellent agents comprising fluorine compounds are known. The water- and oil-repellent agents show good water- and oil-repellency, when substrates such as textiles are treated with the water- and oil-repellent agents. There is a demand for water- and oil-repellent agents which do not contain fluorine compounds, but there is no fluorine-free water- and oil-repellent agent excellent in both of water-repellency and soil resistance.

Summary

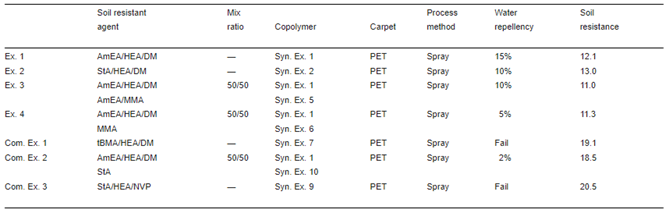

Provided are a fluorine-free soil resistant agent and a soil resistant treatment method which give excellent water-repellency and excellent antifouling property to a substrate, especially a carpet. The soil resistant agent contains (1) a fluorine-free copolymer having (a) a repeating unit formed from an acrylic monomer having a hydrocarbon group containing 7 to 40 carbon atoms, and (b) a repeating unit formed from an acrylic monomer having a hydrophilic group, and (2) water or a mixture of water and an organic solvent dispersing the fluorine-free copolymer. A method of treating the substrate, includes applying the soil resistant agent to the substrate. The fluorine-free polymer can be applied to fibrous substrates (such as textiles) by any known method to treat textiles in liquid. The textile fabric may be immersed in the solution, or the solution may be adhered or sprayed to the fabric. The treated textiles are dried, preferably heated at a temperature between 100° C. and 200° C. to develop the oil repellency.

Urethane compounds for finishing textile sheet materials in a fluorine-free manner

Patent number: EP4355805

Publication date: 2024-04-24

Applicant(s): EVONIK OPERATIONS GMBH

Inventor(s): RICHRATH RUBEN BENEDIKT; PLATTE GABRIELE; PFEIFFER NICOLE; BERGFRIED STEFAN; DAHL VERENA; STREMMER KATHRIN; RADLOFF SARAH; RÖBEN CAREN; BAGUS NINO; VON HOF JAN MARIAN

Background

As an alternative to fluorine-containing finishes, finishes based on simple waxes are known. These waxes consist essentially of long alkyl chains. They have the disadvantage that they give the textile a wax-like texture, the feel of which (also referred to as "handle) rejects many potential users. In addition, such compounds of comparatively simple structure are readily dissolved from the textile during washing with commercially available detergents, because of which the hydrophobicizing action is lost. Improvements can be achieved by crosslinking wax-like components having long alkyl chains together with melamine derivatives to give relatively high molecular weight polymers. However, the disadvantage of such melamine-based compositions is the high active ingredient requirement and the hardness which the melamine active ingredient imparts to the textile.

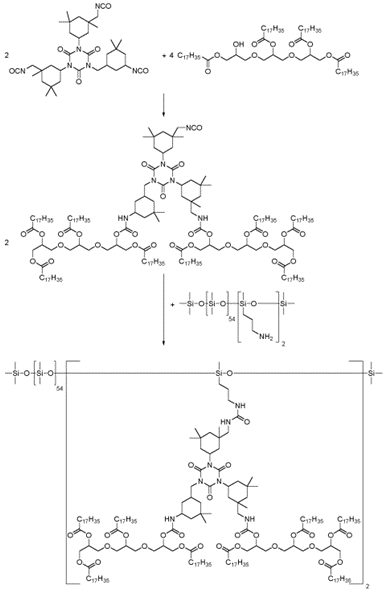

Summary

The invention relates to a urethane compound containing at least one structural unit, said structural unit being a polyglycerol structural unit with at least three groups R1, each of which is selected independently of one another from C3-C39 hydrocarbon groups that optionally contain heteroatoms other than fluorine atoms. The heteroatoms are preferably selected from N, O, S. It is preferred that a radical R1 contains no more than 3 heteroatoms. However, it is more preferred that the radicals R1 are each independently selected from those hydrocarbon radicals which contain no heteroatoms. The invention further relates to a method for producing one or more of the aforementioned urethane compounds; to compositions which contain one or more of the aforementioned urethane compounds; to a method for impregnating textile sheet materials so as to be water- and/or oil-repellant using one or more of the aforementioned urethane compounds; and to textile sheet materials which can be obtained according to the aforementioned method.