NEW: Flexible Scope

During the last BELAC audit, we succeeded in obtaining the extension of the 056-TEST scope to include a section of measurement techniques under 'flexible scope'. This allows us to perform certain new tests or standards under accreditation by self-approval.

Download the pdf to consult the groups of tests and associated products and measured properties covered by the flexible scope

Testing of textiles and plastics - from raw material to finished product - by an independent and accredited laboratory not only results in an important competitive advantage but is also proof of one's respect of consumer safety and well-being.

Measure what is measurable, and make measurable what is not so. Galileo Galilei

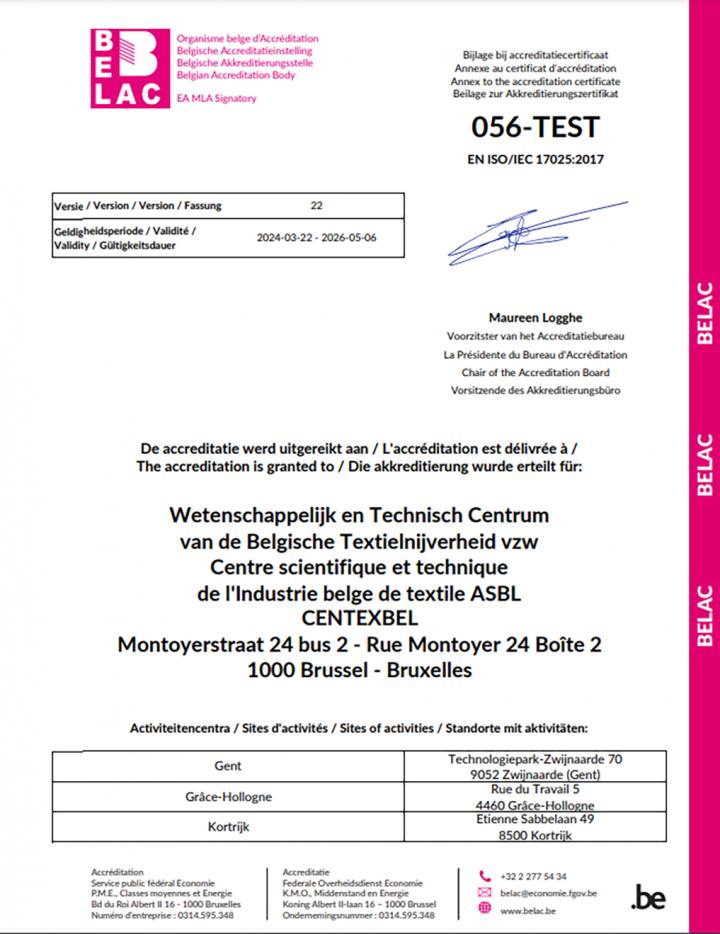

The BELAC EN ISO/IEC 17025 accredited Centexbel laboratories are known for their:

- vast testing offer including several tests that are unique in Europe

- professional advice

- thorough knowledge and follow-up of international standardisation and legislation

- continuous updating and expansion of testing equipment, testing methods, and database of chemical compounds

- accredited tests involving an annual severe audit of all our laboratories

- conditions in conformity with the market

Department of Mobility & Public Works (Flanders/BE)

Lab addresses

Technologiepark 70 - BE 9052 Zwijnaarde

- PPE

- Carpets

- Community masks

- Other textiles for chemical, physical and burning behaviour test

Rue du Travail 5 - BE 4460 Grâce-Hollogne

- Medical devices and masks

- Materials for microbiological tests

- Laser resistance, electrical conductivity, thermo-physiological comfort tests, etc

Etienne Sabbelaan 49 - BE 8500 Kortrijk

- Plastics: virgin and recycled granulates, plastic products